Deepwater Horizon Blowout Animation

Summary

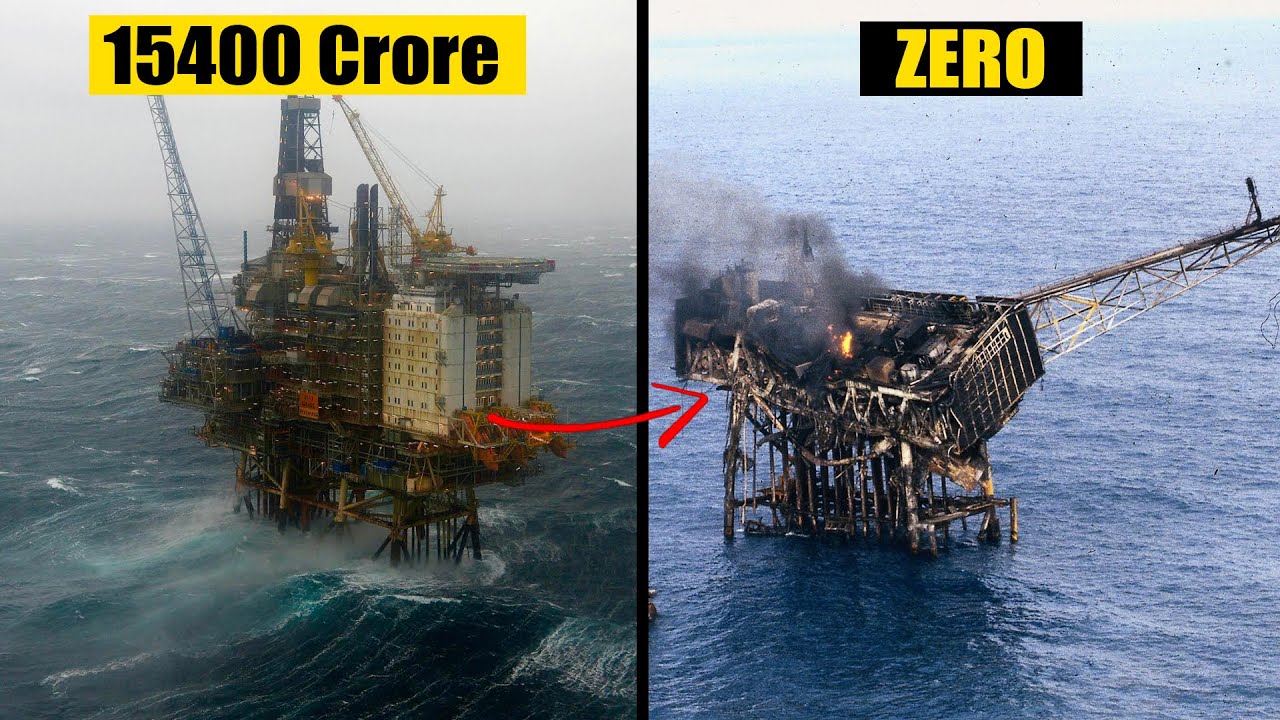

TLDROn April 20, 2010, the Deepwater Horizon offshore drilling rig experienced a catastrophic explosion, killing 11 workers and causing the largest oil spill in U.S. history. The rig was drilling in the Gulf of Mexico when a blowout occurred, resulting in a massive release of oil and gas. Critical failures in the blowout preventer—a key safety device—prevented the well from being sealed. Investigations revealed miswiring and battery failures in the blowout preventer's control systems, as well as a buckled drill pipe, which led to the disaster that spilled millions of barrels of oil into the Gulf over 87 days.

Takeaways

- ⚠️ 11 workers died and 17 were seriously injured due to an explosion on the Deepwater Horizon drilling rig on April 20th, 2010.

- 🔥 The explosion and fire caused the rig to sink, leading to the largest oil spill in U.S. history.

- 🌊 The rig was drilling in the Gulf of Mexico at a depth of 5,000 feet, in an area known as the Macondo Prospect.

- 🛠️ The blowout preventer (BOP), a crucial safety device designed to stop oil flow, failed to seal the well during the emergency.

- 🚨 The accident was triggered by a 'kick,' where oil and gas under pressure entered the well bore undetected.

- 🔧 Despite attempts to close the well using the BOP's pipe rams, oil and gas continued to flow, leading to an explosion.

- ⚡ A significant malfunction occurred due to miswiring in the BOP’s control system, rendering the blind shear ram inoperative.

- 🔋 Backup batteries in the BOP's control pods also failed, further complicating efforts to activate safety measures.

- 📉 The drill pipe inside the BOP buckled under pressure, preventing the blind shear ram from fully cutting the pipe and sealing the well.

- 🌍 Over 5 million barrels of oil spilled into the Gulf of Mexico over 87 days, causing a massive environmental disaster.

Q & A

What caused the initial explosion on the Deepwater Horizon rig on April 20th, 2010?

-The explosion was caused by a 'kick' in the Macondo well, which allowed oil and gas to enter the wellbore and eventually reach the drilling rig. These hydrocarbons found an ignition source, leading to the explosion.

What is a 'kick' in the context of offshore drilling, and why is it dangerous?

-A 'kick' refers to an unplanned flow of well fluids, such as oil, gas, or water, into the wellbore. It is dangerous because it can lead to a blowout, which is the uncontrolled release of flammable materials that can cause fires or explosions on the rig.

What role does drilling mud play in preventing a blowout during offshore drilling?

-Drilling mud is pumped into the well to create a barrier between the oil and gas in the reservoir and the piping leading to the rig. If this barrier fails, it can allow oil and gas to rise up and cause a blowout.

What is a Blowout Preventer (BOP), and how is it supposed to work?

-A Blowout Preventer (BOP) is a complex, electrically and hydraulically powered device located on the sea floor. It is designed to seal the well in case of a kick by closing valves around the drill pipe and, in extreme cases, cutting the pipe to prevent oil and gas from reaching the rig.

Why did the Blowout Preventer (BOP) on the Deepwater Horizon fail to prevent the disaster?

-The BOP failed due to several factors: the drill pipe buckled, pushing it out of the reach of the blind shear ram blades designed to cut the pipe and seal the well. Additionally, wiring issues and battery failures in the BOP's control system contributed to its malfunction.

What is the 'blind shear ram,' and why is it important in preventing blowouts?

-The blind shear ram is a pair of sharp metal blades designed to cut the drill pipe and seal the well in the event of a blowout. It is considered the last line of defense in preventing catastrophic oil spills and explosions.

How did the buckling of the drill pipe contribute to the failure of the BOP on April 20th, 2010?

-The buckling of the drill pipe caused it to shift out of alignment with the blind shear ram. This misalignment meant that the ram could only partially cut the pipe, allowing oil and gas to continue flowing from the well, leading to the massive spill.

What was the role of the AMF Deadman system during the Deepwater Horizon accident?

-The AMF Deadman system is an automated emergency system designed to activate the blind shear ram when electrical and hydraulic power from the rig is lost. On the night of the accident, the system was supposed to close the well, but control failures prevented it from fully operating.

What technical issues were found in the BOP's control system, and how did they affect its operation?

-The BOP's control system had multiple issues, including miswiring of solenoid valves and battery failures. These problems prevented the proper activation of the blind shear ram, which was critical in stopping the blowout.

What was the environmental impact of the Deepwater Horizon oil spill?

-The spill lasted for 87 days and released approximately 5 million barrels of oil into the Gulf of Mexico, making it one of the worst environmental disasters in U.S. history, with severe impacts on marine life and coastal ecosystems.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Deepwater Horizon Blowout Animation

The Biggest Environmental Disaster in U.S. History Never Ended

Were Deepwater Horizon Workers Afraid to Bring Up Safety Issues? | Smithsonian Channel

The Secret of Piper Alpha Oil Rig Disaster lies at the Bottom of the Sea

Sehari Bekerja di Rig Minyak Raksasa di Tengah Laut yang Ganas

Crisis Communication Failures: The British Petroleum Case Study (Done by Jakhongir Ubaydullaev)

5.0 / 5 (0 votes)