Compressed Air Line In Ship-Main air, service air,control air system in Engine Room

Summary

TLDRThis video explains the workings of an air compressor system on a ship. It describes how the main air compressor provides high-pressure air to start diesel engines and low-pressure air for various parts like driving motors. It also covers the control air compressor's role in supplying air for control systems, and the use of an emergency air compressor during power failures. Additionally, it highlights the system's air dryer for moisture removal and the interconnecting valve that ensures low-pressure air for controls during maintenance.

Takeaways

- 🔧 The main air compressor provides high-pressure air to the main air reservoir for starting diesel engines.

- 📦 Air from the main air reservoir is reduced in pressure to supply low-pressure air to components like driving air motors.

- 🚛 Low-pressure air is used to operate gangway motors and other parts of the system.

- 🔩 The control air compressor supplies low-pressure air to the control air reservoir for control systems.

- 💧 An air dryer removes moisture from the air, ensuring dry air throughout the system.

- 🔀 An interconnecting valve supplies low-pressure air for controls by linking the control and service air lines.

- 🛠 During maintenance of the control air compressor, an emergency air compressor can be used independently of the main power system.

- ⚡ The emergency air compressor supplies air to the emergency air reservoir for critical systems during power failures.

- 🔌 Air from the emergency reservoir is used to start generators in case of emergencies.

- 📊 The script references typical technical specifications for compressors for guidance.

Q & A

What is the main purpose of the main air compressor?

-The main air compressor supplies high pressure air to the main air reservoir, where it is stored and used to start diesel engines.

How is low pressure air supplied in the system?

-Air from the main air reservoir passes through a pressure reducing valve to supply low pressure air for other parts, such as driving air motors for gangways.

What does the control air compressor do?

-The control air compressor supplies low pressure air to the control air reservoir, where it is stored and used for control systems.

What role does the air dryer play in the system?

-The air dryer in the system removes moisture completely, ensuring dry air is used in the system.

What is the purpose of the interconnecting valve between the control airline and service airline?

-The interconnecting valve supplies low pressure air for controls during maintenance of the control air compressor.

What happens during the maintenance of the control air compressor?

-During maintenance, an emergency air compressor can be operated independently of the ship's main power system to supply air to the emergency air reservoir.

When is the air in the emergency air reservoir used?

-The air stored in the emergency air reservoir is used for starting generators during power failures or other emergencies.

What is the emergency air compressor’s key feature?

-The emergency air compressor can operate independently of the ship's main power system, providing a backup air supply during emergencies.

Why is moisture removal important in this system?

-Moisture removal is important to prevent damage to system components and ensure efficient air supply, which is achieved by the air dryer.

What are typical technical specifications for compressors mentioned in the script?

-The script refers to typical technical specifications for compressors, although specific details are not provided, it implies that reference values are available.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

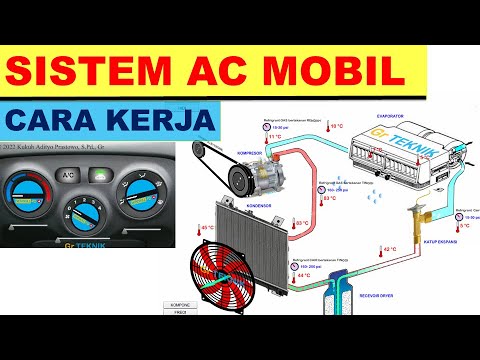

cara kerja sistem ac mobil

How oil screw compressors work | Complete guide to components and working Animation Atlas copco

cara kerja sistem ac mobil dengan animasi siklus refrigasi freon

Cara Kerja Pendingin Udara (AC)

Belajar sirkulasi freon AC untuk pemula agar bisa servis atau perbaiki AC

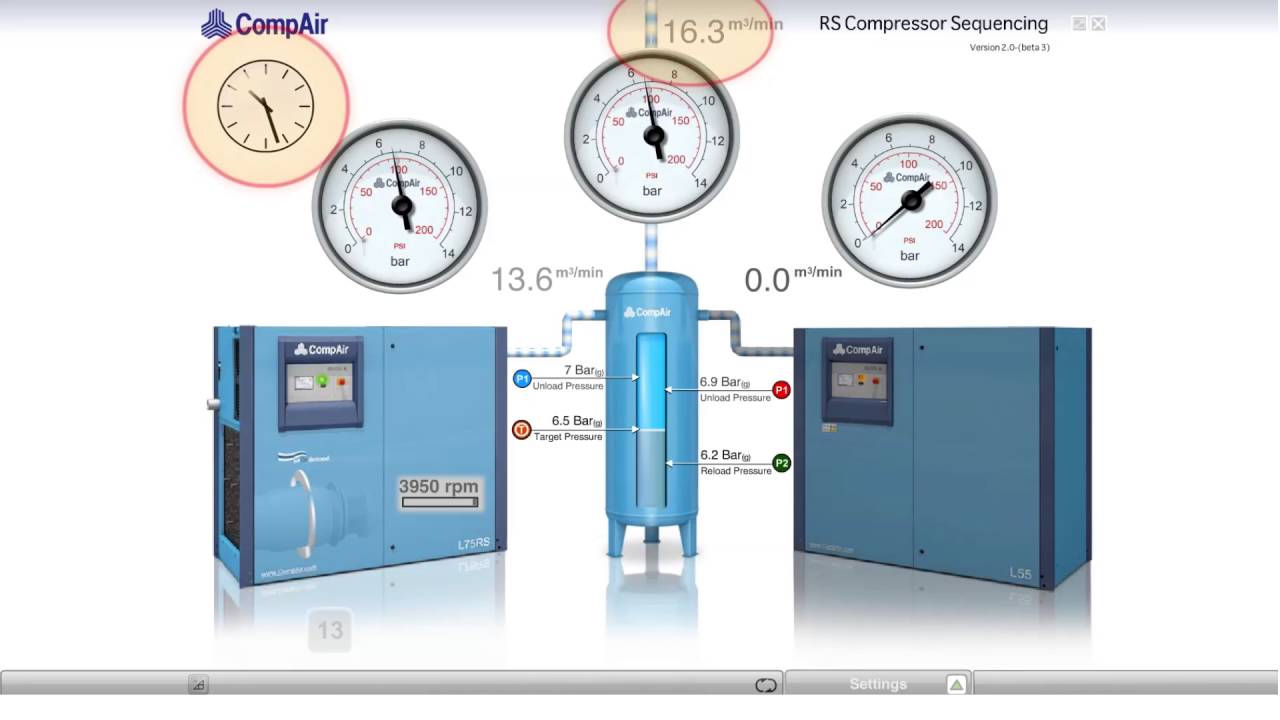

Variable Speed Compressors for Improved Energy Efficiency

5.0 / 5 (0 votes)