Operations Management: Maintenance and Reliability III – Failures & MTBF

Summary

TLDRThis video tutorial explains how to calculate the Mean Time Between Failures (MTBF) and failures per unit hour for a manufacturer of tablet touch screens. It demonstrates the process using test results from 10 units and shows how to determine the percentage of failures, the number of failures per unit hour, and the MTBF. Additionally, the video addresses a case study of a fire department evaluating maintenance options for oxygen masks, comparing the cost of in-house maintenance to outsourcing, and concludes that in-house maintenance is more economical.

Takeaways

- 📊 The video demonstrates how to calculate the Mean Time Between Failures (MTBF) and the number of failures per unit hour.

- 📈 Problem 17.7 involves calculating MTBF for a manufacturer of touch screens, aiming for an MTBF of at least 50,000 hours.

- 🔍 The percentage of failures is calculated by dividing the number of failures by the number of units tested.

- 📉 The number of failures per unit hour (FRN) is determined by dividing the number of failures by the total operating time minus the non-operating time of failed units.

- 📋 A timeline is helpful to visualize when each unit failed to calculate FRN accurately.

- ⏱ MTBF is calculated as the reciprocal of the number of failures per unit hour (1/FRN).

- 💡 MTBF provides a more meaningful measure of reliability than failures per unit hour alone.

- 🚒 Problem 17.17 discusses a fire department evaluating the cost-effectiveness of in-house versus outsourced maintenance for oxygen masks.

- 💼 The expected number of breakdowns per year is calculated by dividing the total number of breakdowns by the number of years with breakdowns.

- 💵 The cost of the current maintenance policy is determined by multiplying the cost per failure by the estimated number of breakdowns per year.

- 💹 The video concludes that in-house maintenance is more economical than outsourcing, based on the given data.

Q & A

What is the MTBF and how is it calculated?

-MTBF stands for Mean Time Between Failures. It is calculated by taking the reciprocal of the number of failures per unit hour (FRN), which is determined by dividing the total operating time by the number of failures.

What are the three requirements for Problem 17.7 in the script?

-The three requirements for Problem 17.7 are: 1) Determine the percentage of failures. 2) Determine the number of failures per unit hour (FRN). 3) Determine the MTBF at this point in the testing.

How is the percentage of failures calculated in the script?

-The percentage of failures is calculated by dividing the number of failures by the number of units tested, resulting in a 40% failure rate in the given example.

What is the formula for calculating FRN (Failures per Unit Hour)?

-FRN is calculated by dividing the number of failures by the total operating time of all units minus the sum of non-operating times of the failed units.

What is the significance of drawing a timeline in the script?

-Drawing a timeline helps visualize when each unit failed, which is crucial for calculating the operating and non-operating times to determine FRN.

What is the MTBF for the touch screen manufacturer in the script?

-The MTBF for the touch screen manufacturer is calculated to be 121,250 hours.

What are the three requirements for Problem 17.17 in the script?

-The three requirements for Problem 17.17 are: 1) Determine the expected number of breakdowns per year. 2) Determine the cost of the current maintenance policy. 3) Discuss which maintenance policy is more economical.

How is the expected number of breakdowns per year calculated in the script?

-The expected number of breakdowns per year is calculated by dividing the total number of breakdowns by the sum of all the years with breakdowns.

What is the estimated cost of the current maintenance policy in the script?

-The estimated cost of the current maintenance policy is $4,444 per year.

What is the cost of outsourcing preventative maintenance in the script?

-The cost of outsourcing preventative maintenance is $5,000 per year.

Which maintenance policy is more economical according to the script?

-The current policy of performing maintenance in-house is more economical, with a savings of $556 per year compared to the outsourced option.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Business Impact Analysis - CompTIA Security+ SY0-701 - 5.2

System Reliability Calculation | Physical Significance of Calculating System Reliability Probability

Cara Menentukan Waktu Berdasarkan Perbedaan Letak Garis Bujur

VELOCIDADE MÉDIA - FÍSICA BÁSICA (FÍSICA do ZERO) - Teoria e Exercícios AULA 02

VELOCIDADE MÉDIA - CINEMÁTICA - Aula 2 - Prof. Marcelo Boaro

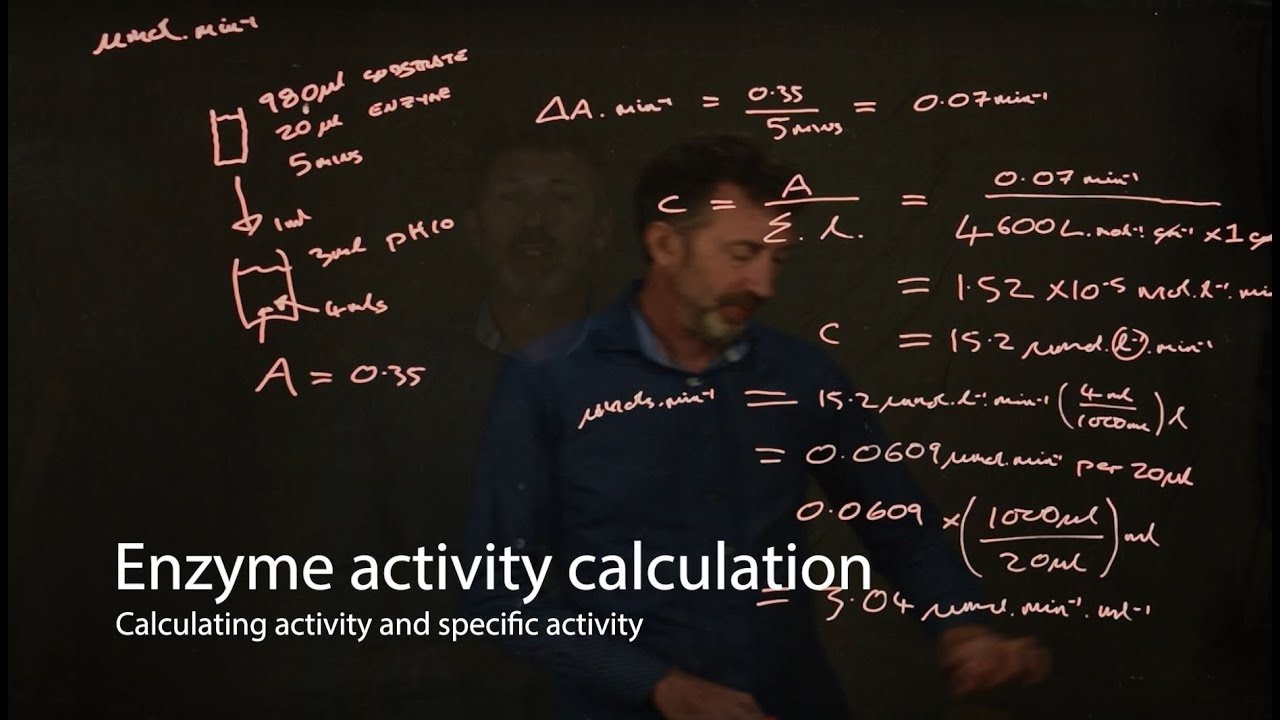

Enzyme calculations - enzyme activity and specific activity

5.0 / 5 (0 votes)