EXTRUSÃO E TREFILAÇÃO

Summary

TLDRThis educational video explores two key mechanical processes: extrusion and drawing. The extrusion process involves pushing heated metal through a die to form various shapes, while drawing pulls metal to reduce its diameter and increase length. The video covers the different types of extrusion, such as hot and cold, and explains the equipment used in drawing, including the die and the wire drawing machine. It also highlights typical defects in these processes and their impact on the quality of the final products. The importance of these processes in creating materials for modern industries, such as telecommunications and construction, is emphasized.

Takeaways

- 😀 Extrusion and drawing (trefilação) are essential mechanical processes in modern manufacturing, enabling the creation of various metal products.

- 😀 Extrusion can be done hot or cold, with hot extrusion being used for harder metals and cold extrusion for more ductile materials like aluminum.

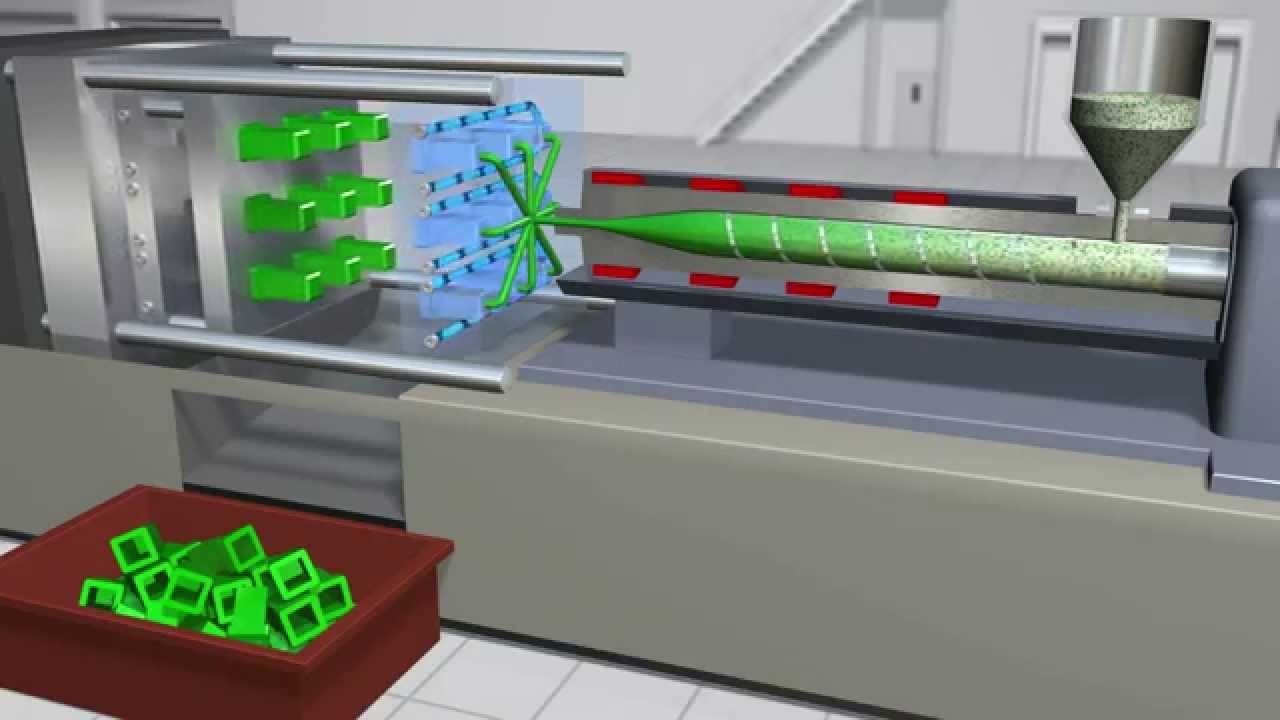

- 😀 The extrusion process involves forcing a metal block (tarugo) through a die under high pressure to form profiles of different shapes.

- 😀 In hot extrusion, the material's temperature must be carefully controlled to prevent oxidation and maintain plasticity for the process.

- 😀 Extrusion defects include uneven deformation, formation of cavities in the metal, and surface issues such as tearing and bubbles.

- 😀 Trefilação (drawing) is used to reduce the diameter of metals, creating long, continuous products like wires and cables, often done cold.

- 😀 The drawing process uses machines with multiple bobbins, pulling the metal through a die to reduce its diameter and increase its length.

- 😀 The die in the drawing process, called a fieira, has a funnel-like shape that helps reduce friction and controls the diameter of the wire.

- 😀 Drawing defects include irregularities like diameter variations, fractures caused by poor lubrication, and issues from inadequate material reduction.

- 😀 Both extrusion and drawing are crucial for producing components like telephone cables, steel wires, and electrical wiring, impacting everyday items like bikes and TVs.

Q & A

What are the main processes discussed in the script?

-The main processes discussed in the script are extrusion and drawing (trefilation), both of which are mechanical forming processes used in manufacturing various metal products.

How does the extrusion process work?

-In extrusion, a block of metal is pushed through a die by a piston. This process can be done hot or cold, depending on the material's properties. The metal is forced through a die to create a specific shape or profile, such as rods, cables, or plastic packaging.

What are the differences between hot and cold extrusion?

-Hot extrusion involves heating the metal to a high temperature to make it more ductile, allowing for larger deformations, while cold extrusion is done at room temperature, resulting in harder materials due to work hardening.

What types of metals can be processed using extrusion?

-Extrusion can be used to process various metals, including aluminum, copper, carbon steel, and stainless steel. These materials are commonly used in manufacturing components like cables, wires, and profiles.

What are the key defects associated with the extrusion process?

-Common defects in extrusion include uneven deformation, the formation of cavities in the metal, tearing of the surface, and gas bubbles trapped in the material due to improper melting or oxidation.

How does the drawing process (trefilation) work?

-Drawing involves pulling a metal wire through a die to reduce its diameter and increase its length. This process typically uses machines that pull the material through progressively smaller dies, often with the addition of lubrication to reduce friction.

What types of products are typically produced by the drawing process?

-The drawing process is mainly used to produce long, continuous metal wires or rods, which are used in industries like construction (for mechanical reinforcement) and electrical applications (for wiring).

What are the two types of drawing machines mentioned in the script?

-The two types of drawing machines mentioned are the dry drawing machine (without sliding) and the wet drawing machine (with lubrication). The wet method is used for smaller diameter wires and helps reduce friction.

What is a 'fieira' and what role does it play in the drawing process?

-A fieira is a cylindrical tool that contains a hole through which the wire passes. The hole gradually decreases in size to reduce the wire's diameter. It is crucial in controlling the wire's shape and ensuring consistent quality.

What are some common defects observed in drawn products?

-Defects in drawn products include stepped diameter (due to hard particles in the die), irregular fractures caused by insufficient lubrication, lateral cracks, and inclusions from particles that get embedded in the wire during the process.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Materiais e Processos de Fabricação para Engenharia de Produção - Extrusão e Trefilação

Aprenda os processos de CONFORMAÇÃO / FABRICAÇÃO - Laminação, trefilação, extrusão e forjamento

Pechakucha Els Plàstics Tecnologia 3 ESO MRejon Martin

Plastic Processing Overview

Fisiologi Lengkap Sistem Pencernaan (Deglutisi, Propulsi, Digestasi, Abrosbsi, Defekasi)

Vulkanisme (Gunung Berapi)/Geografi Kelas X SMA/ Kurikulum Merdeka

5.0 / 5 (0 votes)