Preparation of an organic liquid – practical video | 16–18 years

Summary

TLDRThis video explains the process of preparing pure 2-chloro-2-methylpropane, an organic liquid, through a multi-step procedure. It covers three key steps: preparation, separation, and purification. The reaction involves 2-methylpropan-2-ol with hydrochloric acid, followed by separating the organic layer using a separating funnel. Purification is achieved through neutralization with sodium hydrogen carbonate and drying with sodium sulfate. The final step is distillation to obtain the pure product. The video emphasizes safety, proper laboratory techniques, and the chemistry behind each step for successful synthesis of the organic liquid.

Takeaways

- 😀 Organic compounds are essential in daily life, and many chemists are involved in their production.

- 😀 The process of preparing 2-chloro-2-methylpropane involves three main steps: preparation, separation, and purification.

- 😀 Safety is crucial in the lab, and eye protection should always be worn when working with concentrated hydrochloric acid.

- 😀 The first step in the synthesis of 2-chloro-2-methylpropane is reacting 2-methylpropan-2-ol with concentrated hydrochloric acid.

- 😀 When performing the reaction, ensure to add the alcohol slowly (one cm³ at a time) to the acid and swirl after each addition.

- 😀 After the reaction, a separating funnel is used to separate the organic layer (product) from the aqueous layer.

- 😀 The aqueous layer is more dense than the organic layer, and it should be removed first in the separating funnel.

- 😀 To purify the organic product, any remaining hydrochloric acid can be neutralized with sodium hydrogen carbonate solution.

- 😀 After neutralization, the aqueous layer should be removed again, and the organic product is collected.

- 😀 Anhydrous sodium sulfate is added to remove trace water from the organic liquid, and this is followed by filtration.

- 😀 Finally, distillation is used to purify the organic product further, with the product being collected between 49°C and 52°C.

- 😀 Throughout the process, ensure to handle the distillation setup properly, with water flowing from the bottom to the top of the condenser.

Q & A

Why should the reaction of 2-methylpropan-2-ol with concentrated hydrochloric acid be performed in a fume cupboard?

-The reaction should be performed in a fume cupboard to ensure proper ventilation and safety, as concentrated hydrochloric acid can release harmful fumes during the reaction.

Why is it important to keep the hydrochloric acid cold during the preparation step?

-Keeping the hydrochloric acid cold slows down the reaction rate, which helps control the reaction and prevents excessive heat generation that could be hazardous.

What is the purpose of using mineral wool or cotton wool to plug the neck of the conical flask?

-The wool plug prevents vapors from escaping during the reaction, while still allowing some airflow to prevent pressure buildup inside the flask.

How do you ensure the proper separation of the organic and aqueous layers during the separation step?

-By carefully draining the aqueous layer from the separating funnel, ensuring the tap is closed before adding the mixture, and removing the stopper to allow gas to escape, you can successfully separate the two layers.

What is the significance of effervescence during the neutralization of hydrochloric acid with sodium hydrogen carbonate?

-Effervescence indicates that carbon dioxide is being released as a result of the neutralization reaction between hydrochloric acid and sodium hydrogen carbonate, signaling that the acid is being neutralized.

Why should you not shake the separating funnel when mixing the solutions?

-Shaking the separating funnel can lead to dangerous pressure buildup, which could cause the funnel to burst. Instead, gentle swirling should be done to safely mix the contents.

What is the role of anhydrous sodium sulfate in the purification process?

-Anhydrous sodium sulfate acts as a drying agent, binding with any remaining water in the organic liquid and allowing for its removal, ensuring the final product is as pure as possible.

Why do you need to filter the organic liquid into a pear-shaped flask after drying it with sodium sulfate?

-The pear-shaped flask is ideal for distillation and ensures that any solid sodium sulfate left behind during the drying process is filtered out, leaving only the pure organic liquid.

What is the purpose of adding anti-bumping granules during the distillation process?

-Anti-bumping granules are added to prevent the liquid from boiling too violently, which can lead to splashing and uneven distillation.

Why is it important to collect the distillation product between 49°C and 52°C?

-Since 2-chloro-2-methylpropane has a boiling point of 51°C, collecting the product between 49°C and 52°C ensures that the purified liquid is the desired product and not contaminants with different boiling points.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Stereoisomers

Cara Membuat Kompos Dari Sampah Rumah Tangga Pakai Ember

PRAK. KE-1B. ISOLASI RHIZOBIUM - BIOTEK PERTANIAN (Lab. Biotan Faperta Unpad)

PULSAR II™ ADVANCED WOUND IRRIGATION (AWI)™ WOUND DEBRIDEMENT SYSTEM Application Video

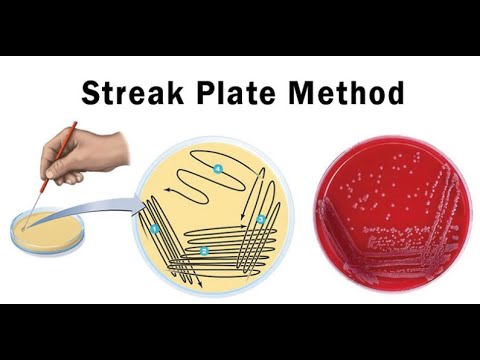

Lab technique microbiology: Streak plate method

Administer Oral Medications

5.0 / 5 (0 votes)