Ship Construction Animation

Summary

TLDRThis video script delves into the unique aspects of the shipbuilding industry, highlighting its customization based on owner requirements, unlike unit production industries like automobiles. It outlines the shipbuilding process, starting from material procurement and stowage to plate preparation, cutting, bending, and assembly. The script also covers the crucial stages of ship launching, outfitting, and sea trials, emphasizing the intricate coordination among various departments to ensure the vessel's seaworthiness and operational efficiency.

Takeaways

- 🚀 The shipbuilding industry is distinct from others due to its non-standardized, unit-based production, where each ship is custom-built according to the owner's requirements.

- 🔖 After a contract is signed and a detailed design is completed, the shipyard's tendering department procures materials specified for the ship's construction.

- 📏 Steel plates, once procured, are stored in the stockyard, with different thicknesses and grades available in standard dimensions, and are organized for efficient use.

- 🛠️ Plate preparation involves straightening and stress removal to ensure the plates are ready for construction after being received from the steel plant.

- 💧 Priming and drying are essential steps where a primer, often a zinc-rich coating, is applied to protect the steel from corrosion and ensure it doesn't interfere with welding and bending.

- ✂️ Plate cutting is the process of cutting the surface-treated plates into the desired shapes and sizes for the ship's construction.

- 🔄 Plate bending is a complex process where steel plates and stiffeners are shaped into the required 3D curvatures to fit the hull's design.

- 🔩 Assembly involves welding the prepared plates and frames according to structural drawings, with the hull divided into blocks for efficient construction.

- 🚢 Launching involves flooding the building dock or using traditional methods to move the ship into the outfit basin, where further outfitting takes place.

- 🌊 Sea trials are conducted to test the ship's performance, including turning circle, crash stop, zigzag maneuvers, and engine trials, ensuring the ship is seaworthy and efficient.

Q & A

Why does the shipbuilding industry differ from other manufacturing industries in terms of production?

-The shipbuilding industry differs from other manufacturing industries because it is not based on unit production. Unlike industries like automobile manufacturing that produce similar units on assembly lines, each ship is built according to the owner's specific requirements, resulting in unique dimensions, capacities, and systems even if the basic hull design is similar.

What is the first step in the shipbuilding process after signing a contract and completing the detailed design?

-The first step in the shipbuilding process after signing a contract and completing the detailed design is the procurement of materials. The tendering department of the shipyard procures the materials specified by the design, which includes the type, thickness, and grade of steel required for each part of the hull.

How are steel plates stored in a shipyard?

-Steel plates in a shipyard are stored either in vertical stowage or horizontal storage. Modern shipyards may also practice plate storage scheduling, where each plate is marked with the project it is designated for and stored in an order that aligns with the shipyard's working schedule.

What is plate preparation and why is it necessary?

-Plate preparation, also known as surface preparation, is necessary because plates obtained from steel plants are not ready for construction and may not be perfectly straight or may have been damaged during transit. This process includes straightening the plates and removing residual stress to ensure they are suitable for use in ship construction.

What is the purpose of priming and drying in the shipbuilding process?

-Priming and drying is a crucial step in the shipbuilding process where a primer is sprayed onto the complete surface of the plate. This priming protects the steel from corrosion, and the primer used is typically a zinc-rich coating chosen to not interfere with welding and bending of plates.

How are steel plates cut and shaped for shipbuilding?

-Steel plates are cut into desired shapes and sizes to develop the required three-dimensional shapes or to be used as straight plates for other structural components. This is done using plate cutting techniques that follow the specifications outlined in the detailed design.

What is plate bending and why is it important in shipbuilding?

-Plate bending is the process of shaping steel plates and stiffeners to achieve the required 3D curvatures to fit the shape of the ship's hull. It is important because a ship's hull usually has multiple curvatures, and bending the plates accurately is crucial for the structural integrity and the overall design of the ship.

How are the plates and frames assembled in the shipbuilding process?

-The plates and frames are assembled according to the structural drawings prepared by the design department. The hull is divided into blocks, which are further divided into assemblies and sub-assemblies. These are then welded together in the building dock using cranes and proper welding techniques, ensuring proper alignment and structural integrity.

What is the purpose of launching a ship and how has this process evolved?

-Launching a ship is the process of moving it from the building dock to the water. This process has evolved to become safer and more proactive, with modern shipyards using building docks that can be flooded to float the ship out, or traditional methods that involve careful planning and computer-aided load estimation to ensure a successful launch.

What happens during the outfitting stage of shipbuilding?

-During the outfitting stage, the ship is berthed in a fitting out basin for completion. This includes the installation of main machinery, auxiliaries, piping systems, deck gear, live boards, accommodation equipment, plumbing systems, and rigging, along with any necessary insulation and deck coverings.

What are sea trials and why are they conducted?

-Sea trials are conducted after all construction and outfitting work is completed. They involve testing the ship's performance at sea in the presence of the ship's owner's representative and a ship surveyor. Tests include turning circle, crash stop, zigzag, spiral maneuvers, engine trials, and other assessments to ensure the ship is seaworthy and operates efficiently.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

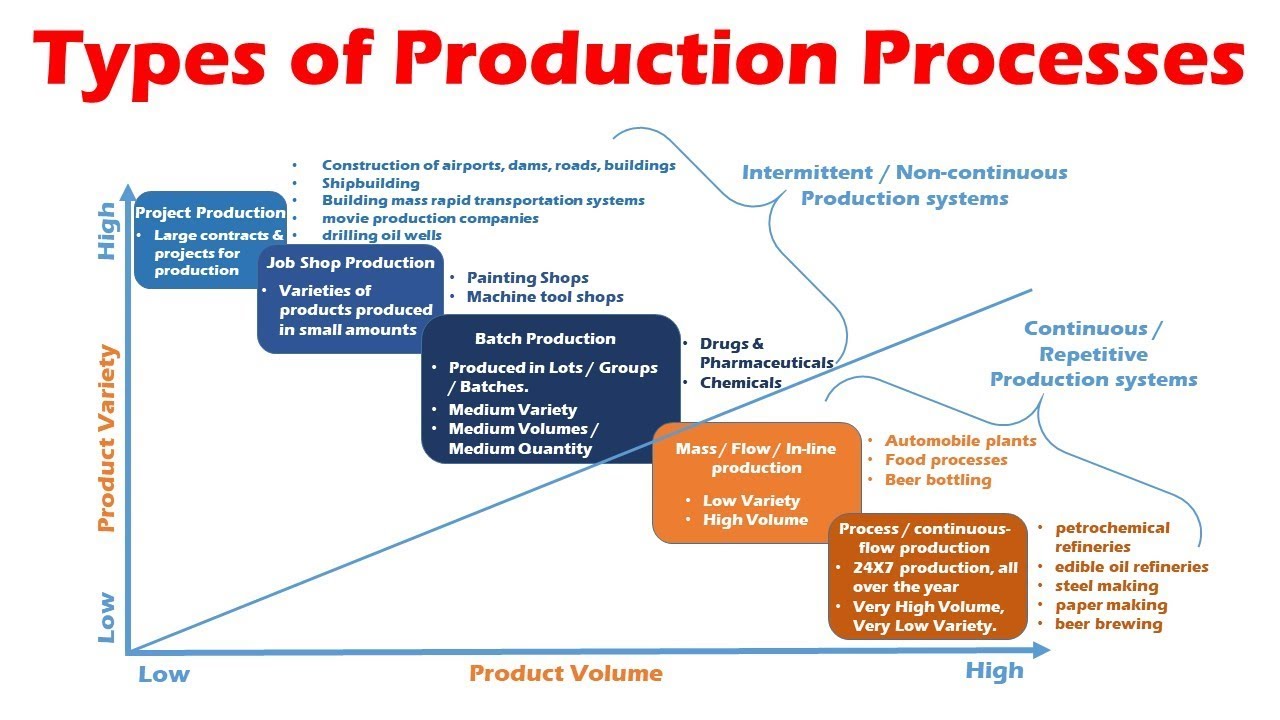

Types of Production Systems (Process, Mass, Flow, Batch, Job Shop & Project Production Systems)

What is Production? Types of Production, Factors of Production

History of the assembly line part A | What is an assembly line | Business History

Manila During American Occupation (1920s)

Manufacturing Industry Overview - A Galco TV Tech Tip | Galco

Internet of Things (IoT) and its Applications in Manufacturing

5.0 / 5 (0 votes)