Most Common DIYer Electrical Mistake - Don't Let This Be You!

Summary

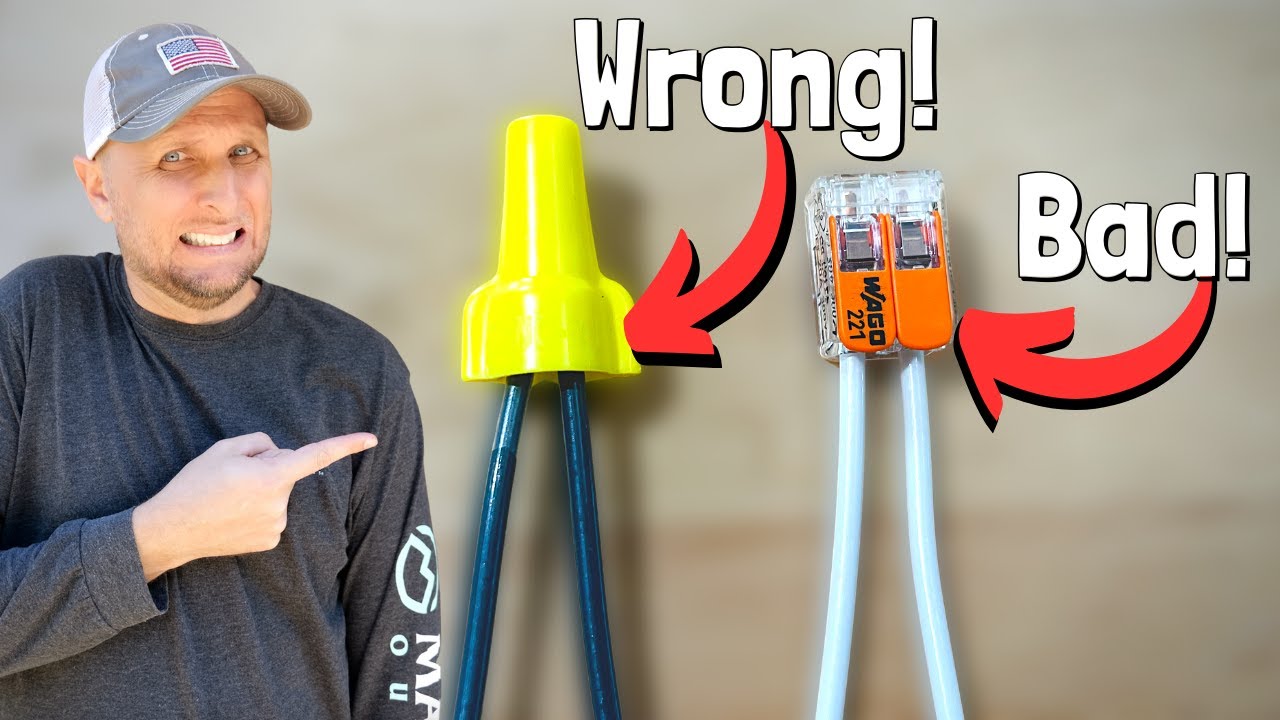

TLDRIn this video, Scott from Everyday Home Repairs demonstrates the common mistake made when connecting stranded wire to solid core wire, often seen in light fixtures and smart switches. He highlights the risk of loose connections leading to heat, arcing, or fire hazards. Scott then shows the correct technique using a wire net and the best practices, including a preferred method with AWG 221 connectors for a consistent and secure connection. He emphasizes the importance of proper wire connection for safety and durability in DIY electrical projects.

Takeaways

- ⚠️ The number one mistake made by DIYers when connecting wires is combining stranded wire with solid core wire, which is common in light fixtures and smart switches.

- 🔥 A loose connection can cause additional heat, reduce the life of connections, and potentially lead to arcing or short circuits, posing a fire hazard.

- 🛠 To connect stranded and solid core wires properly, use a wire net and follow best practices to ensure a strong connection.

- 📏 When stripping wire, use the correct gauge for stranded and solid core, and avoid pulling at an angle or wiggling the strippers to prevent damage.

- 👍 Pre-twist stranded wires to avoid frayed strands and ensure a secure connection within the wire nut.

- 🔧 The correct approach is to lead with the stranded wire when connecting, ensuring the wire nut bites into the stranded wire, not just the solid core.

- 💡 WAGO 221 connectors are recommended for DIYers as they provide a consistent and reliable connection, especially for those new to electrical work.

- 🔌 WAGO 221 connectors are lever nuts, not push-in connectors, and are approved for use with both stranded and solid core wires.

- 💰 While WAGO connectors are more expensive than wire nuts, their reusability and reliability make them a good investment for DIYers.

- 🔗 WAGO 221 connectors have been tested and proven to handle loads up to three times their rated capacity without failure.

- 🌍 In European markets, WAGO lever nuts are more common than wire nuts due to their consistent and solid connection quality.

Q & A

What is the main mistake that DIYers make when connecting stranded wire to solid core wire?

-The main mistake is not ensuring a tight connection, which can result in a loose connection that may lead to additional heat in the junction box, arcing, or even a fire hazard.

Why is it important to avoid a loose connection when connecting wires in electrical work?

-A loose connection can lead to increased heat, which might reduce the life of the connections, and in the worst case, cause arcing or a short circuit, posing a fire hazard.

What is a wire net and how is it used incorrectly in the script's example of a common failure?

-A wire net is a tool used to secure wires together. In the example, the wire net was biting into the solid core wire, but the stranded wire was just loosely wrapped around it, leading to a weak connection that could be pulled out easily.

What is the correct way to connect stranded wire to solid core wire using a wire nut?

-The correct way is to lead with the stranded wire, inserting only about an eighth of an inch into the wire nut, ensuring that the wire nut bites into the stranded wire properly, creating a strong connection that won't come loose.

Why is it recommended to pre-twist solid core wires before putting a wire nut on?

-Pre-twisting solid core wires helps to ensure a more consistent and secure connection, even though wire nut manufacturers usually advise against it and suggest letting the wire nut do the work.

What is the recommended method for DIYers to connect stranded to solid wires according to the script?

-The script recommends using WAGO 221 connectors, also known as lever nuts, as they provide a more consistent connection and are easier for DIYers to use correctly.

What are WAGO 221 connectors and why are they preferred by the script's author?

-WAGO 221 connectors are a type of electrical connector that uses lever nuts for a secure connection. They are preferred because they offer a consistent connection, are approved for use with stranded wires, and are reusable.

How do WAGO 221 connectors ensure a secure connection with stranded wires?

-WAGO 221 connectors have a bus bar that fully seats the wires when the lever is closed, ensuring a secure connection. They are also designed to accommodate both solid and stranded wires.

Why are WAGO 221 connectors more common in European markets according to the script?

-In European markets, WAGO 221 connectors are more common because they provide a solid and consistent connection, which is preferred for their reliability.

What is the main advantage of using WAGO 221 connectors over wire nuts for temporary light fixtures in renovation projects?

-The main advantage is that WAGO 221 connectors are reusable. They can be easily removed from the wires without damaging them, making them ideal for temporary setups where wires need to be disconnected and reconnected.

How can one find a sample kit of WAGO 221 connectors as mentioned in the script?

-A sample kit of WAGO 221 connectors can be found in the description of the video, which likely contains a variety of pin sizes suitable for different wiring projects.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

7 FATAL Wiring Mistakes Most DIYers Don't Know They Are Making | Most Are Guilty of 3

How To Hide TV Power Cord And Cables | Easy Way To Move An Outlet

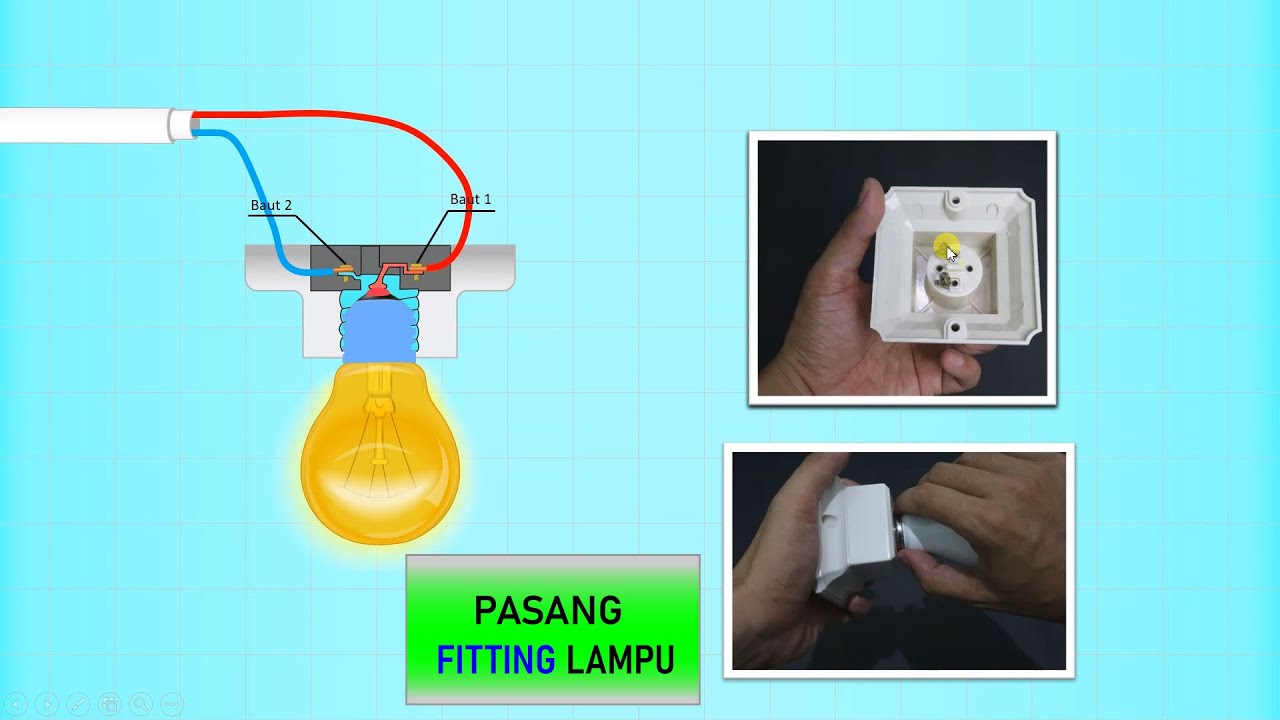

instalasi listrik prakarya kelas 9.

Begini Cara Pasang Fitting Lampu Sesuai PUIL

#1 Circuitos Elétricos em Série - IFÍSICA

Cara Kontrol On/Off Motor Listrik dengan Kontaktor

5.0 / 5 (0 votes)