LEAN MANUFACTURING (Manufatura Enxuta) | Conheça os 8 Principais Tipos de Desperdícios

Summary

TLDRThis video explains Lean Manufacturing, a methodology focused on optimizing processes, minimizing waste, and maintaining quality. Originating from Toyota's production system, it aims to solve common business challenges such as unnecessary transportation, defects, excessive stock, and overproduction. The benefits include improved productivity, quality, cost-efficiency, and motivated teams. It also discusses essential tools like Kanban, JIT, and 5S for effective implementation. Overall, Lean Manufacturing helps businesses streamline operations, reduce waste, and deliver higher value to customers, while providing a flexible and efficient approach to production management.

Takeaways

- 😀 Lean manufacturing is a methodology aimed at optimizing processes and reducing waste while maintaining expected quality. It was created by Toyota in the post-war period and is also known as the Toyota Production System.

- 😀 The methodology helps businesses, especially small and medium-sized companies, reduce waste, improve productivity, and maintain high quality in their production processes.

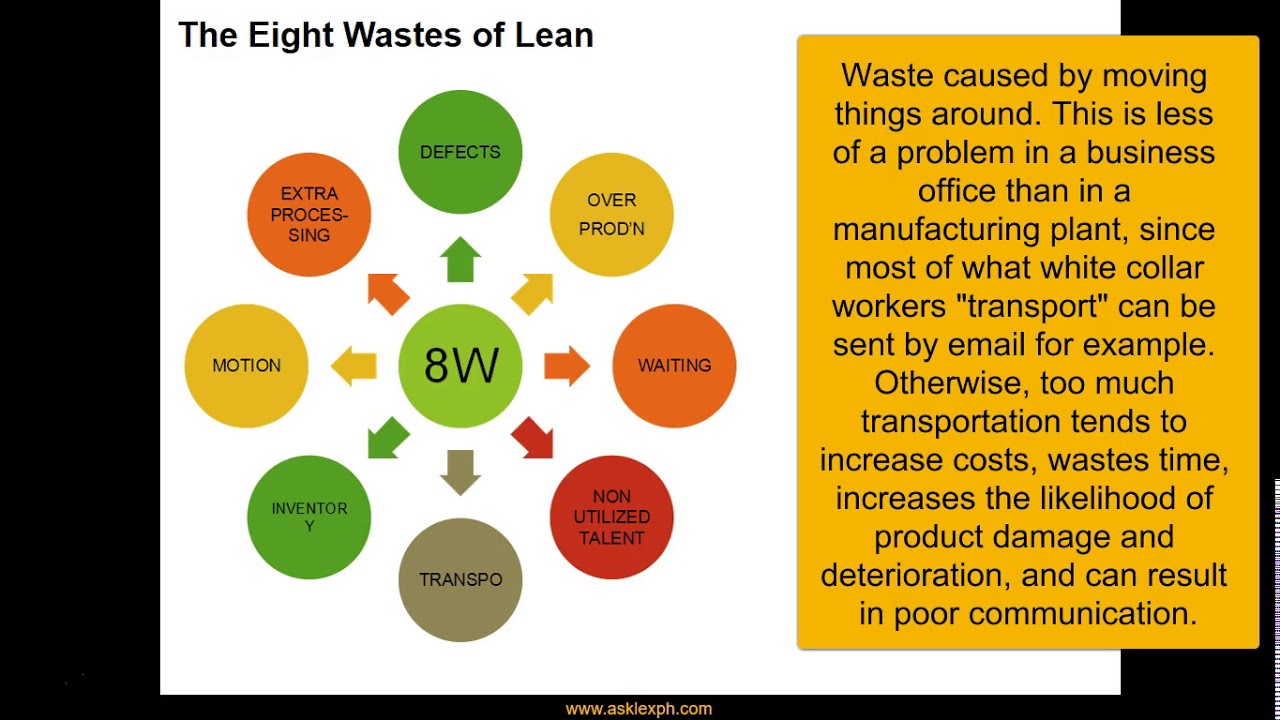

- 😀 Lean manufacturing solves eight main sources of waste, including unnecessary transportation, excessive movement of people, long waiting times, excessive stock, defects in products, excessive processing, underutilization of human potential, and overproduction.

- 😀 Minimizing unnecessary transportation can reduce damage to products and equipment while also saving time and effort in the production process.

- 😀 Reducing excessive movement and long displacements of people and materials within the workplace helps avoid unnecessary waste of time and energy.

- 😀 Lean manufacturing emphasizes the importance of minimizing waiting times caused by issues like communication errors, equipment malfunctions, or supplier delays to avoid production stoppages.

- 😀 Managing stock effectively is crucial to avoid both excess stock, which ties up money, and insufficient stock, which can lead to shortages and missed opportunities.

- 😀 Defects in products represent waste, as they lead to rework or rejection, which increases costs and reduces productivity.

- 😀 Excessive production, or producing more than necessary, can result in unnecessary costs and products that do not meet market demand, ultimately leading to wasted resources.

- 😀 The three main advantages of lean manufacturing are reducing waste, optimizing production processes, and prioritizing quality. These improvements lead to increased profitability and more efficient use of resources.

- 😀 Tools like Kanban, Just-In-Time (JIT), and 5S are effective methods for implementing lean manufacturing principles, enhancing productivity, efficiency, and safety in the workplace.

Q & A

What is lean manufacturing?

-Lean manufacturing is a management methodology aimed at optimizing processes and reducing waste. It was created by Toyota and focuses on minimizing errors while maintaining the expected quality in production processes.

What are the main factors that lean manufacturing addresses in order to reduce waste?

-Lean manufacturing addresses eight main factors to reduce waste: unnecessary transportation, excessive movement, waiting time, stock, defects, excessive processing, underutilization of human potential, and excessive production.

How does lean manufacturing help in reducing unnecessary transportation?

-Lean manufacturing reduces unnecessary transportation by organizing the flow of materials, products, and people, ensuring that they are moved only when necessary, which prevents damage to goods and improves productivity.

What is the importance of reducing movement in lean manufacturing?

-Reducing movement minimizes the unnecessary travel of employees or materials, which helps in improving efficiency and productivity. This is achieved through better planning of the workspace and organizing the workflow.

Why is reducing waiting time crucial in lean manufacturing?

-Reducing waiting time is crucial because it minimizes idle resources such as machinery, raw materials, and employees. It is often linked to errors or delays in processes, so optimizing the process flow helps eliminate unnecessary waiting.

How can stock management be optimized in lean manufacturing?

-Stock management in lean manufacturing is optimized by ensuring that the right amount of stock is available at the right time. This prevents overstocking, which ties up company resources, and understocking, which can lead to insufficient supply to meet demand.

What are the risks of excessive production in lean manufacturing?

-Excessive production leads to waste because it can result in products that are not demanded, leading to obsolete stock. It can also mean products are rushed through production, resulting in defects and reduced quality.

How does lean manufacturing improve product quality?

-Lean manufacturing prioritizes quality by reducing errors, detecting failures early in the process, and ensuring that production is streamlined and efficient. This helps maintain high standards and avoid delivering defective products.

What are the benefits of applying lean manufacturing in terms of company productivity?

-The main benefits of lean manufacturing include increased productivity due to optimized production processes, reduced waste, and better utilization of resources, all of which contribute to more efficient operations and higher profitability.

Can lean manufacturing be flexible enough to meet unexpected demands or seasonality?

-Yes, lean manufacturing is flexible and can be adjusted to meet unexpected demands or seasonality. The processes are designed to be reorganized and scaled up or down as needed without compromising efficiency or quality.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)