Tutorial Dasar Penggunaan Mesin Las TIG Untuk Pemula - Daesung TIG 200

Summary

TLDRIn this video, the process of preparing for TIG welding (Tungsten Inert Gas welding) is discussed in detail. The video covers the tools and equipment required, such as the Daesung TIG 200 machine, argon gas for shielding, and a tungsten electrode. It also highlights safety measures, including the use of protective gear and ensuring a dry body to prevent issues during welding. The tutorial emphasizes the importance of proper equipment setup, including grounding, connecting the trigger switch, and adjusting the tungsten electrode. Viewers will learn essential techniques for precise and effective TIG welding.

Takeaways

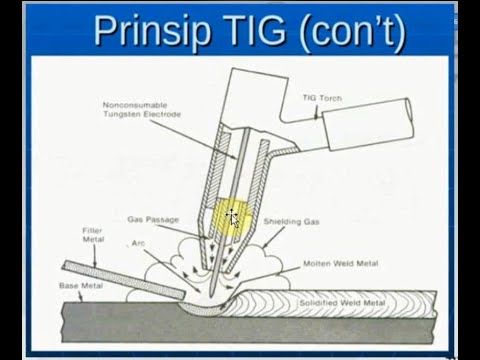

- 😀 The video focuses on preparation for TIG (Tungsten Inert Gas) welding, a process that uses a non-consumable tungsten electrode and argon gas for shielding.

- 😀 TIG welding is ideal for thin materials that require high precision, such as stainless steel and aluminum.

- 😀 As with MMA welding, safety equipment is essential before starting the welding process.

- 😀 The video introduces the Daesung Daily Sunti 200 welding machine, highlighting its features, including digital display and dual modes: TIG and MMA.

- 😀 The necessary accessories for TIG welding include the TIG torch, ground clamp, gas hose, argon gas, and a tungsten electrode (in red and green colors).

- 😀 Proper body conditions, such as being dry and sweat-free, are crucial before starting the welding process to ensure comfort and focus.

- 😀 The video details the process of connecting the power cable, attaching the ground clamp to the negative terminal, and securing the ground clamp to the welding material.

- 😀 Proper handling of the TIG torch and trigger switch is demonstrated to ensure smooth operation during welding.

- 😀 The argon gas should be connected securely with a regulator and hose clamp to prevent leaks, as it's vital for protecting the weld pool from oxidation.

- 😀 The video emphasizes the importance of sharpening the tungsten electrode regularly to maintain a stable arc, with green tungsten suitable for AC welding of aluminum and magnesium.

Q & A

What is the purpose of the Argon gas in TIG welding?

-Argon gas is used as a shielding gas in TIG welding to protect the weld pool from oxidation and contamination by the surrounding air, ensuring a clean and strong weld.

What is the significance of using Tungsten in TIG welding?

-Tungsten is used as the electrode in TIG welding due to its high melting point and ability to maintain a stable arc. It does not melt during the process, allowing for precise and controlled welding.

What types of materials are commonly welded using TIG welding?

-TIG welding is commonly used for welding thin materials that require high precision, such as stainless steel and aluminum.

Why is it important to ensure the body is dry before starting the welding process?

-It is crucial to ensure the body is dry to avoid electrical shock risks and to maintain clear vision and concentration during the welding process.

What is the role of the ground clamp in the TIG welding setup?

-The ground clamp connects to the material being welded and the negative terminal of the welding machine, completing the electrical circuit necessary for the welding process.

What is the difference between the green and red Tungsten electrodes?

-Green Tungsten electrodes are used for AC welding and are suitable for welding aluminum and magnesium, while red Tungsten electrodes are used for DC welding.

Why must the Tungsten electrode be sharpened before use?

-Sharpening the Tungsten electrode ensures that the arc remains stable and directed. A pointed Tungsten electrode provides better control over the weld pool and overall quality.

What should be checked before starting the welding process?

-Before starting, ensure that all safety equipment is worn, the welding machine is set up properly with the right accessories, and that the necessary tools such as gas hoses and regulators are securely connected.

What safety measures should be followed during TIG welding?

-Proper safety equipment, such as protective gloves, goggles, and a welding helmet, should be worn. Additionally, ensure that the workspace is free of moisture, and that the body is dry to prevent electrical hazards.

What are the benefits of using the Daesung TIG 200 welding machine?

-The Daesung TIG 200 welding machine features digital display settings for easy adjustments, an LGBTI technology for better performance, and dual-mode functionality, supporting both TIG and MMA welding methods.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)