Pitch sobre Fluência

Summary

TLDRThis video explains the phenomenon of creep in materials, which refers to the slow, progressive deformation that occurs under constant temperature and stress. It discusses the impact of high temperatures, stress, and grain size on the rate of creep in materials like turbine blades, industrial piping, and nuclear reactors. The video also introduces mechanisms like diffusion, dislocation motion, and grain boundary sliding, which explain how materials deform under stress. Understanding creep is crucial not just for ensuring the safety of critical infrastructure but also for broader material science applications.

Takeaways

- 😀 Fluency is a phenomenon where materials slowly deform over time even without movement, caused by the accumulation of plastic deformation.

- 😀 Fluency occurs in all materials under constant temperature and stress, and its effects are more pronounced at high temperatures.

- 😀 High-temperature applications, like airplane turbines and industrial steam pipes, require materials to resist fluency in order to avoid catastrophic failures.

- 😀 Temperature is a crucial factor influencing fluency, with higher temperatures providing more energy that increases atomic movement and deformation.

- 😀 Applied stress also affects fluency: higher stress leads to greater initial deformation and a faster fluency rate.

- 😀 The elasticity modulus of a material determines its resistance to fluency. Materials with a higher modulus are harder to deform.

- 😀 The grain size of materials plays a significant role, with larger grain sizes improving resistance to fluency due to reduced dislocation sliding.

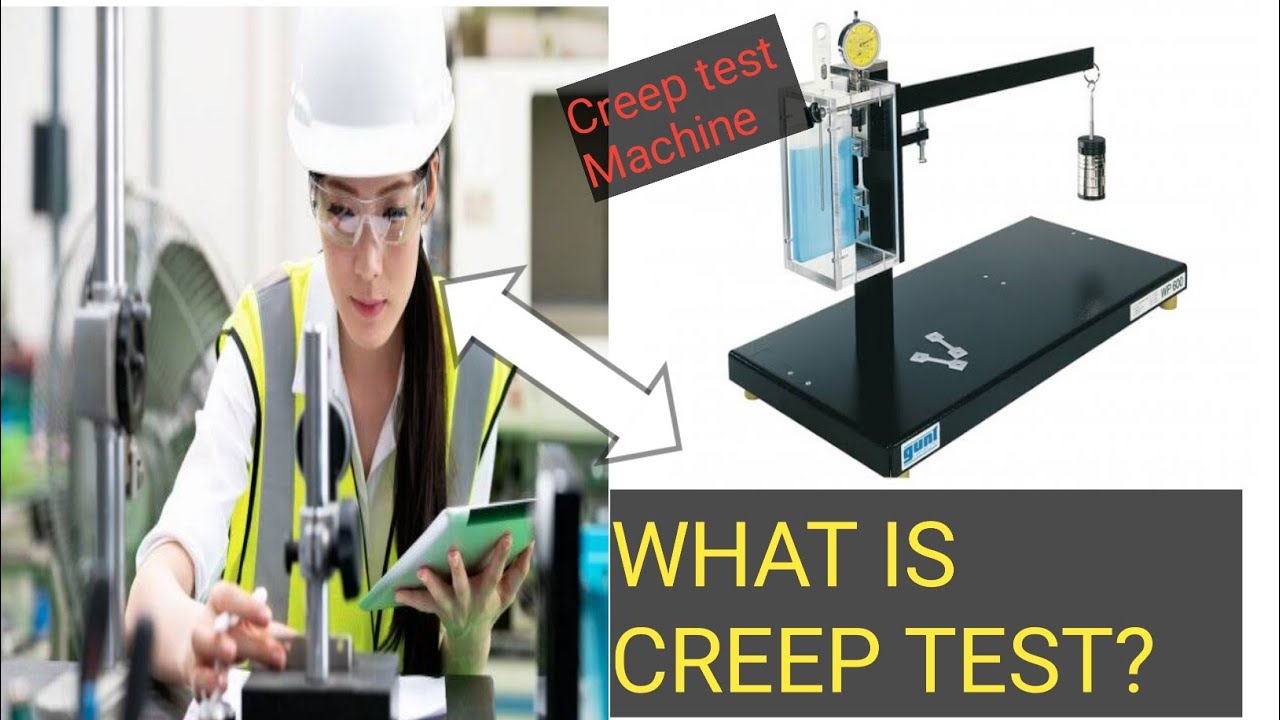

- 😀 Fluency tests are conducted using standardized samples (like circular or rectangular) and follow specific standards (ASM E8 and E139).

- 😀 A fluency test produces a curve with three stages: initial deformation, steady fluency rate, and rapid increase in fluency leading to material failure.

- 😀 Several mechanisms explain fluency in metals, including diffusion mechanisms (Navarro Erin and Coble) and dislocation sliding, which occur at different temperatures.

Q & A

What is creep in materials?

-Creep is the slow and progressive accumulation of plastic deformation in materials under constant temperature and applied load. It is a time-dependent phenomenon where materials deform over time even without external movement.

What materials exhibit creep?

-Creep is observed in all materials under constant temperature and load conditions, but it is particularly significant in materials exposed to high temperatures, such as turbine blades in airplanes, steam pipes in industrial settings, and materials in nuclear reactors.

Why is creep important in high-temperature applications?

-In high-temperature environments, materials need to maintain their integrity to prevent catastrophic failures. Creep resistance is crucial for components like turbines and reactors, as these materials are subjected to extreme heat and mechanical stress.

What are the main factors affecting creep in metals?

-The primary factors influencing creep in metals are temperature, applied stress, the material's modulus of elasticity, and grain size. Higher temperatures and stresses lead to increased deformation and creep rates.

How does temperature affect the creep process?

-As temperature increases, the energy provided to the system also increases, which facilitates the movement of dislocations and other imperfections in the material, leading to higher creep rates and deformation.

What role does the material's modulus of elasticity play in creep?

-The modulus of elasticity measures the rigidity of the material. Materials with higher elasticity resist deformation more effectively, which means they also have better resistance to creep.

How does grain size influence creep resistance?

-Materials with larger grain sizes have greater resistance to creep because coarser grain structures make it more difficult for dislocations to move across grain boundaries.

How are creep tests conducted on materials?

-Creep tests are performed using standard test specimens, which can be circular or rectangular, and the tests are conducted under controlled temperature and load conditions. The results provide a creep curve, which characterizes the material's behavior over time.

What are the three stages of a creep curve?

-The three stages of a creep curve are: 1) The initial stage, where rapid deformation occurs; 2) The steady-state stage, where the rate of deformation stabilizes; and 3) The tertiary stage, where deformation accelerates and the material eventually fractures.

What are the primary mechanisms responsible for creep in metals?

-The main mechanisms behind creep include dislocation movement, diffusion of vacancies in the crystal lattice, and grain boundary sliding. These mechanisms work in combination and are influenced by temperature, stress, and the material's microstructure.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)