Carbon Nanotube Review, Definition, Structure, Properties, Applications

Summary

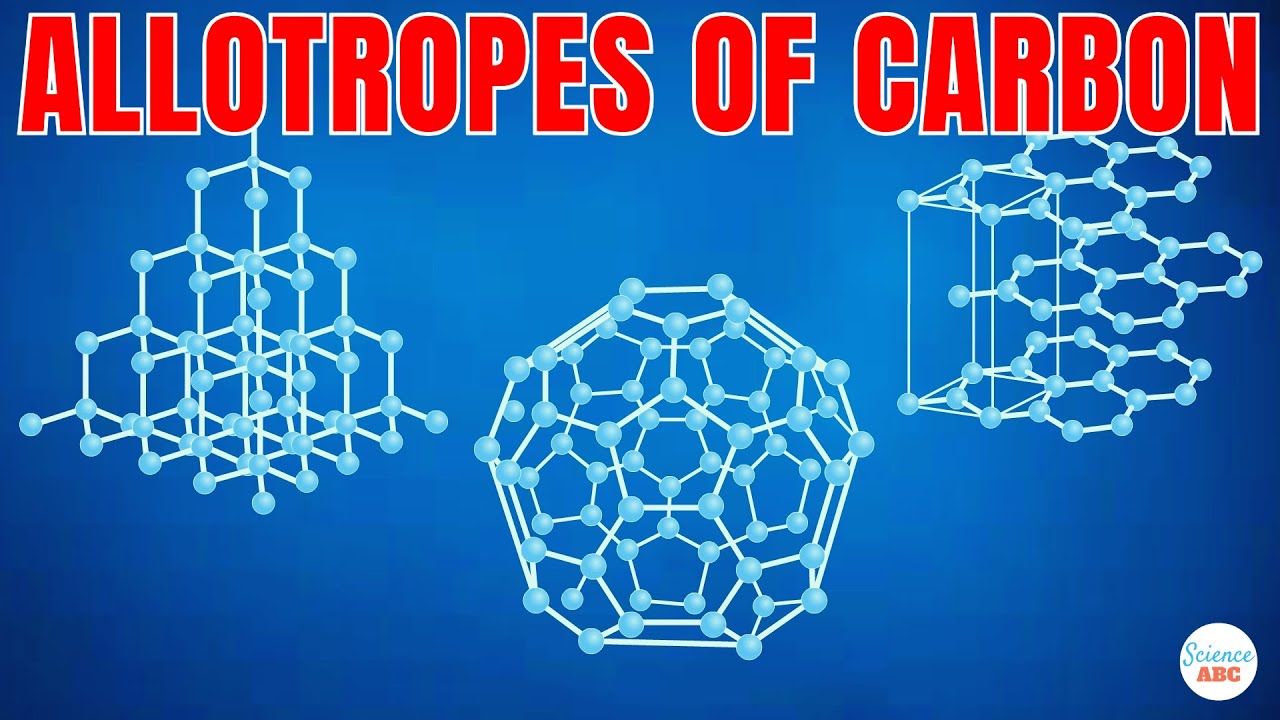

TLDRThis video explores the fascinating world of carbon nanotubes (CNTs), highlighting their structure, unique properties, and diverse applications. Carbon nanotubes, formed from rolled-up graphene sheets, exhibit remarkable strength, electrical conductivity, and thermal properties. The video delves into their potential in fields like nanomedicine, electronics, and composite materials, as well as their challenges in fabrication, purity, and cost. With their ability to revolutionize industries, carbon nanotubes continue to be a key focus of cutting-edge research in nanotechnology.

Takeaways

- 😀 Carbon nanotubes (CNTs) are cylindrical structures made of carbon atoms, and they are known for their strength, conductivity, and thermal properties.

- 😀 CNTs are formed by rolling up graphene sheets, and the resulting structure can be classified into three types: zigzag, armchair, and chiral carbon nanotubes.

- 😀 The electrical properties of CNTs depend on their structure. They can be metallic, quasi-metallic, or semiconducting based on the cut and roll-up direction of the graphene sheet.

- 😀 Single-walled CNTs exhibit ballistic transport, allowing electrons to travel through without scattering, making them ideal for applications requiring low resistance.

- 😀 CNTs are around 400 times stronger than steel, lightweight, and have exceptional mechanical properties due to strong sp² bonds between carbon atoms.

- 😀 CNTs have excellent thermal conductivity, surpassing that of diamond, and are useful for heat dissipation in electronic devices.

- 😀 The hollow interior of CNTs can be used for drug delivery in nanomedicine, allowing the encapsulation and protection of drugs until they reach their target.

- 😀 CNTs are being explored for various applications, including advanced electronics, materials science, and composites to strengthen products without adding significant weight.

- 😀 Despite their potential, challenges remain in fabricating high-quality CNTs at large scales, as well as issues related to the cost and purity of production.

- 😀 The cost of producing CNTs is currently high, and large-scale, cost-effective production methods need to be developed for widespread adoption.

- 😀 Toxicity concerns regarding CNTs are still being researched, especially regarding their potential environmental and health impacts.

Q & A

What are carbon nanotubes (CNTs) made of?

-Carbon nanotubes (CNTs) are cylindrical structures made of carbon atoms, typically measured in nanometers. They can be visualized as rolled-up sheets of graphene, a one-atom-thick layer of carbon atoms arranged in a hexagonal network.

How are different types of carbon nanotubes formed?

-Different types of carbon nanotubes are formed depending on how the graphene sheet is cut and rolled. Zigzag CNTs are formed by cutting graphene in one direction, armchair CNTs by cutting perpendicular to the zigzag, and chiral CNTs are formed by combining both structures.

What is the significance of the notation system used for carbon nanotubes?

-The notation system for carbon nanotubes (n, m) defines the roll-up vectors of the graphene lattice. It helps identify the specific type of nanotube formed, such as zigzag (m=0), armchair (n=m), or chiral (n≠m).

What determines whether a carbon nanotube is metallic or semiconducting?

-A carbon nanotube's metallic or semiconducting properties are determined by its structure. If n=m, the nanotube is metallic. If n-m is a multiple of 3, the nanotube is quasi-metallic with a small bandgap. Otherwise, it is a semiconductor.

What are the electrical transport properties of single-walled carbon nanotubes?

-Single-walled carbon nanotubes exhibit ballistic electrical transport, meaning that electrons move with minimal scattering, allowing the nanotube to conduct electricity with almost zero resistance.

What are the mechanical properties of carbon nanotubes?

-Carbon nanotubes are incredibly strong, about 400 times stronger than steel, while being much lighter. This makes them ideal for use as a filler in composites, providing high strength without increasing weight.

How do carbon nanotubes compare to diamonds in terms of thermal conductivity?

-Carbon nanotubes have superior thermal conductivity compared to diamonds, meaning they dissipate heat more effectively, which is advantageous for electronic applications where heat management is crucial.

What applications are carbon nanotubes used for in consumer products?

-Carbon nanotubes are used to reinforce materials like polymers in consumer products such as tennis rackets, enhancing strength without adding significant weight.

How can carbon nanotubes be used in nanomedicine?

-In nanomedicine, the hollow interiors of carbon nanotubes can be filled with drugs or other materials, providing a way to deliver substances directly to targeted areas while shielding them from the surrounding environment.

What challenges are associated with the widespread use of carbon nanotubes?

-Challenges include difficulties in fabricating carbon nanotubes with consistent properties, high production costs, concerns about toxicity, and issues related to integrating them into practical, large-scale applications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)