¿Cómo funciona un BIORREACTOR?

Summary

TLDRIn this video, César Huallpa explains the critical role of bioreactors in biotechnology, highlighting their use in industries such as brewing and pharmaceuticals. He covers the importance of maintaining optimal conditions for biological reactions, like pH and temperature, and introduces the Stirred-Tank Bioreactor (STR), a common type used in both lab and industrial settings. The video also discusses the bioreactor's mixing system, sensors for monitoring variables, and actuators to adjust conditions, providing a comprehensive overview of how these essential tools support efficient production in biotechnology.

Takeaways

- 😀 A bioreactor is a vessel where biological reactions occur, such as alcoholic fermentation in the brewing industry to produce ethanol.

- 😀 Yeasts, bacteria, animal cells, plant cells, and even enzymes can act as the workers that carry out biological reactions inside a bioreactor.

- 😀 For optimal performance, bioreactors must maintain ideal working conditions including pH, temperature, aeration, agitation, and other variables.

- 😀 Bioreactors come in various sizes, from small-scale laboratory models (like 3L) to large industrial ones (over 500L), depending on the application.

- 😀 Small-scale bioreactors are used for initial research, while large-scale ones are needed for mass production of products.

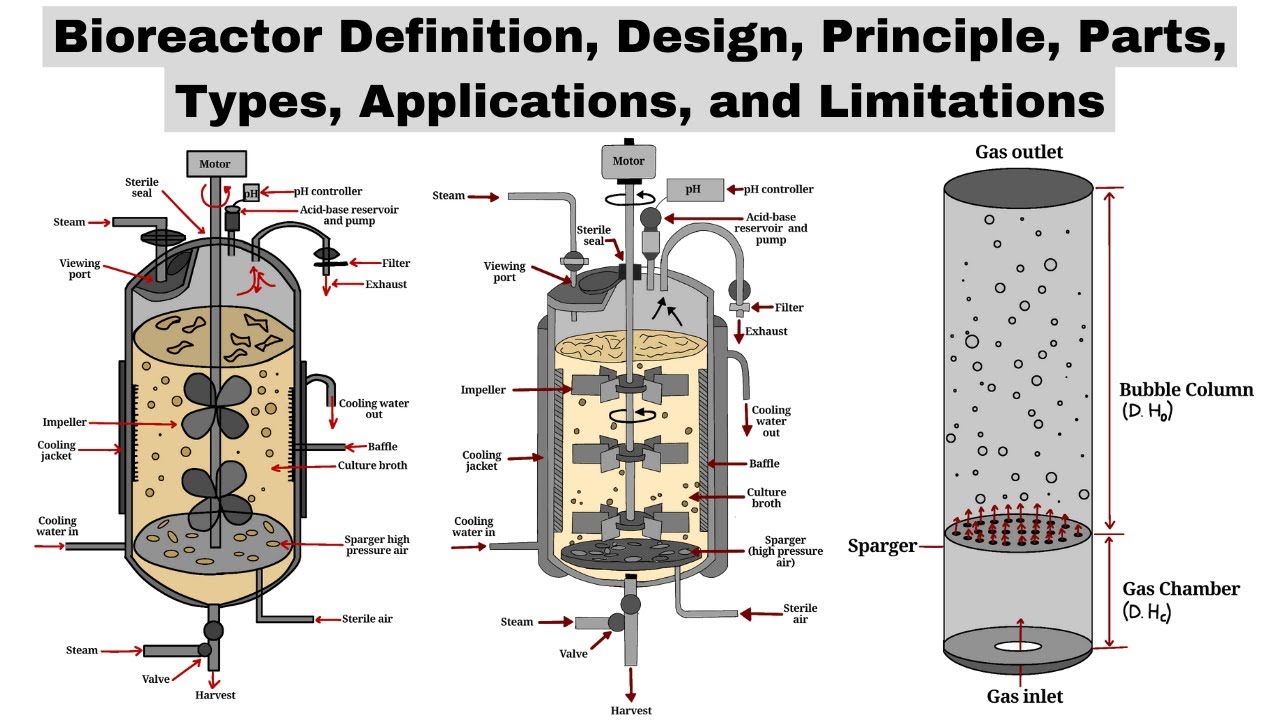

- 😀 The Stirred-Tank Bioreactor (STR) is a popular type used both in laboratories and industrial settings, characterized by a tank where biological reactions occur.

- 😀 In a stirred-tank bioreactor, bladed turbines rotate to mix the contents, similar to a kitchen blender.

- 😀 Baffles inside the bioreactor help improve mixing by disrupting the liquid flow, similar to the internal thickenings found in a blender.

- 😀 Sensors on the lid of a bioreactor monitor key variables, sending data to a controller that helps manage fluctuations in conditions like pH.

- 😀 Actuators in the bioreactor's control system respond to fluctuations by performing actions, such as pumping acid when the pH becomes too high.

- 😀 The optimal moment to stop the bioreactor for product recovery is crucial in industrial biotechnology to ensure high product yield and quality.

Q & A

What is the main purpose of a bioreactor?

-A bioreactor is a vessel where biological reactions occur, typically to produce products such as ethanol through processes like fermentation. It is essential in industries like brewing and pharmaceuticals.

Which biological agents are commonly used in bioreactors?

-Bioreactors commonly use microorganisms such as yeasts, bacteria, animal cells, plant cells, and even enzymes to carry out biological reactions.

How do bioreactors vary in size, and why?

-Bioreactors come in various sizes, from small laboratory models (e.g., 3L) to large industrial-scale versions (e.g., 500L). The size depends on the application: smaller sizes are used for initial research, while larger sizes are needed for mass production.

What is the Stirred-Tank Bioreactor (STR), and why is it popular?

-The Stirred-Tank Bioreactor (STR) is a widely used type of bioreactor for both laboratory and industrial applications. It includes a tank where biological reactions take place, and its mixing system ensures the proper conditions for efficient reactions.

What role do stirring systems play in bioreactors?

-Stirring systems in bioreactors, similar to a kitchen blender, include a motor and blades that rotate to mix the contents of the tank. This ensures that the biological agents and raw materials are evenly distributed, promoting efficient reactions.

What are baffles in a bioreactor, and what is their function?

-Baffles are vertical thickening elements inside the bioreactor that help to improve the mixing process by preventing the liquid from swirling in a vortex, ensuring better contact between the biological agents and the raw materials.

What factors must be controlled within a bioreactor for optimal performance?

-To ensure efficient biological reactions, factors such as pH, temperature, aeration, and agitation need to be monitored and controlled within the bioreactor.

How are fluctuations in variables like pH monitored and controlled in a bioreactor?

-Fluctuations in variables are monitored through sensors placed on the bioreactor lid, which are connected to a controller. When a fluctuation occurs, actuators like peristaltic pumps can be used to counteract it, such as pumping acid to lower the pH when necessary.

Why is it important to control the timing of when to stop the bioreactor?

-Timing the cessation of the bioreactor is crucial because it allows for the optimal recovery of the product before the reaction becomes inefficient or harmful, ensuring high-quality yields.

What is the role of yeast in the fermentation process in bioreactors?

-Yeast plays a key role in alcoholic fermentation, where it converts sugars like maltose and glucose into ethanol. This process is commonly used in brewing and other alcoholic beverage production.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Plant Bioreactor

Bioreactors | Design, Principle, Parts, Types, Applications, & Limitations | Biotechnology Courses

Govt Approves BioE3 Policy to Propel High-Performance Biomanufacturing in India | UPSC

Regelkringen in productie- en procesinstallaties

What is a Boiler and How does It Work?

BAB 3 BIOLOGI KELAS X KURIKULUM MERDEKA

5.0 / 5 (0 votes)