Why do High Voltage Ceramic Insulators have Discs? | An In-Depth Exploration

Summary

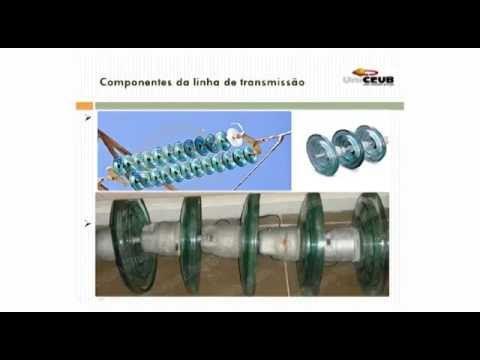

TLDRThis video explores the significance of high voltage ceramic insulators, focusing on their unique disc shapes and vital roles in electrical systems. These insulators prevent unwanted current flow and withstand environmental stresses, making them essential for safe power transmission. The disc design enhances electrical insulation and mechanical strength while minimizing risks of breakdown and contamination. Additionally, the video discusses the advantages of ceramic materials, their manufacturing process, and maintenance techniques to ensure optimal performance. Overall, it highlights the engineering behind these seemingly simple components that are crucial to our electrical infrastructure.

Takeaways

- 🔌 High voltage ceramic insulators prevent unwanted electrical flow to the ground and are essential in electrical systems.

- 🏗️ Made from high-strength porcelain, these insulators offer durability and excellent insulating properties.

- ⚡ The disc shape of ceramic insulators is designed to improve electrical insulation and reduce voltage stress.

- 🧊 Using a series of discs divides the potential difference, lowering the risk of electrical breakdown and flashover.

- 🌪️ The design helps distribute mechanical stresses evenly, preventing failure under tension from wires and environmental factors.

- 💧 Disc shapes minimize the risk of contamination from dust and pollutants, helping maintain insulation performance.

- 🌍 Ceramic insulators are resistant to corrosion, making them suitable for harsh outdoor environments.

- 🔄 Various types of ceramic insulators exist, including pin-type, suspension-type, and strain insulators for different applications.

- 🔥 The manufacturing process involves shaping raw materials, glazing, and firing at high temperatures for optimal strength.

- 🛠️ Regular inspections and advanced cleaning techniques are necessary to maintain the performance and efficiency of insulators.

Q & A

What are high voltage ceramic insulators and why are they important?

-High voltage ceramic insulators are critical components in electrical systems that prevent the unwanted flow of current to the ground. They ensure the safety and efficiency of power transmission.

What materials are used to make ceramic insulators?

-Ceramic insulators are typically made from high strength porcelain, which is known for its durability and excellent insulating properties.

Why were ceramic insulators introduced in the 1950s?

-Ceramic insulators replaced older glass insulators due to their superior performance, longevity, and ability to withstand high voltage applications.

What is the purpose of the disc shape in ceramic insulators?

-The disc shape improves electrical insulation by acting as barriers to electric current, dividing the potential difference among the discs and reducing the risk of electrical breakdown.

How do disc-shaped insulators help with mechanical strength?

-The disc design distributes mechanical stresses evenly along the insulator string, preventing mechanical failure from tension, wind pressure, and other environmental factors.

How do ceramic insulators manage environmental factors like pollution?

-The disc shape increases the surface area, making it harder for contaminants to form a continuous conductive path. Additionally, rain and wind can effectively clean the insulator surfaces.

What are the different types of high voltage ceramic insulators mentioned in the video?

-The video mentions pin type insulators, suspension type insulators, and strain insulators, each designed for specific voltage applications and stress conditions.

What advantages do ceramic insulators have over other types?

-Ceramic insulators offer superior hardness, wear resistance, corrosion resistance, and thermal conductivity, ensuring longevity and consistent performance in harsh environments.

What are some methods used for maintaining ceramic insulators?

-Regular inspections and cleaning methods such as ultrasonic cleaning and high-pressure washing are employed to maintain the efficiency and reliability of ceramic insulators.

What key factors contribute to the design and manufacturing of ceramic insulators?

-The design involves careful engineering to enhance electrical insulation, mechanical strength, and resilience to environmental conditions, ensuring they meet high standards for high voltage applications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

A-13 TRANSMISSÃO DE ENERGIA ELÉTRICA : AVALIAÇÃO DOS ISOLADORES

sistem transmisi listrik

Jenis – jenis isolator

High Voltage Engineering क्या है ? Introduction of High Voltage Engineering #highvoltage #hve #viral

Low Voltage Switchgear : A Beginner’s Guide | TheElectricalGuy

Transformer | Electric Transformer | Types of Transformer | Losses in Transformer in Hindi | Stepup

5.0 / 5 (0 votes)