Ceramic Processing L6-15 Isostatic pressing

Summary

TLDRThe video discusses isostatic pressing, a method that applies uniform pressure from all directions using fluid to transfer force, enhancing material density and strength. It outlines two primary setups: the right-back isostatic pressing, which uses hydraulic fluid and a soft container for powders, and the dry bag method, employing a rubber diaphragm to separate the powder from hydraulic fluid. While the right-back method is suited for complex shapes and larger samples, the dry bag approach is simpler and used for smaller applications. The challenges and messiness of the processes are also acknowledged, emphasizing their use in specialized situations.

Takeaways

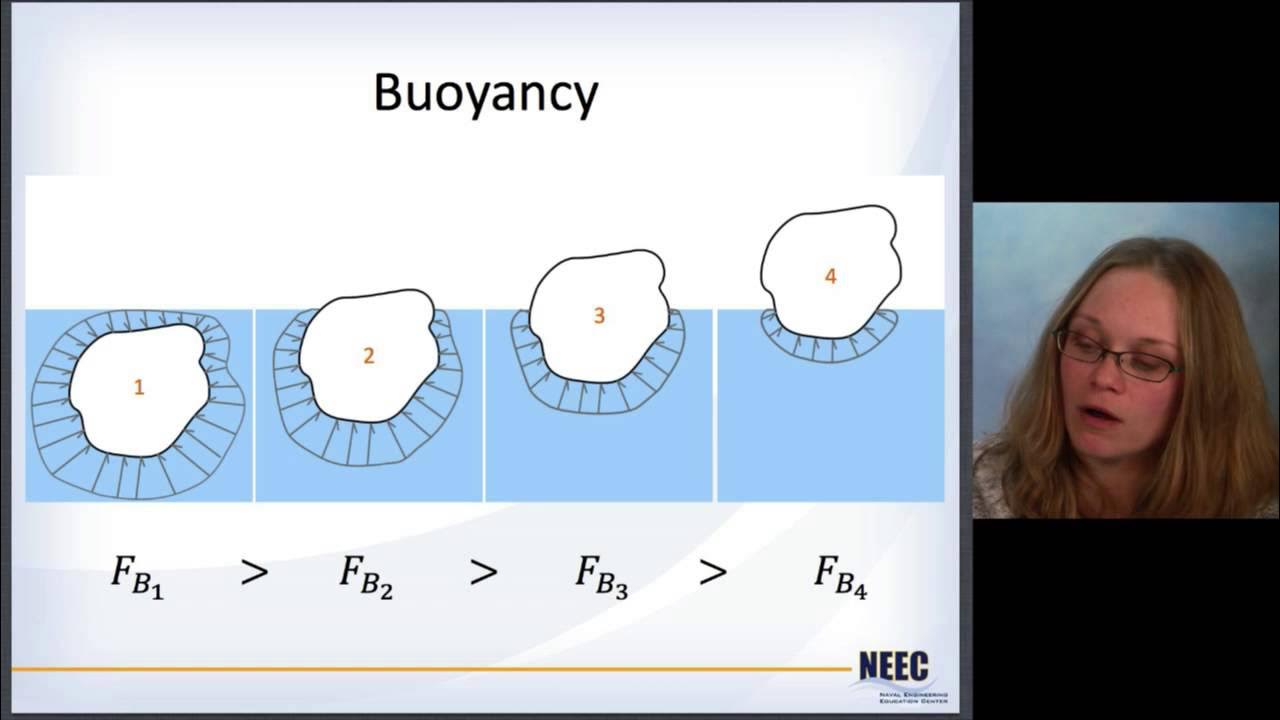

- 😀 Isostatic pressing involves applying uniform pressure from all directions using a fluid medium.

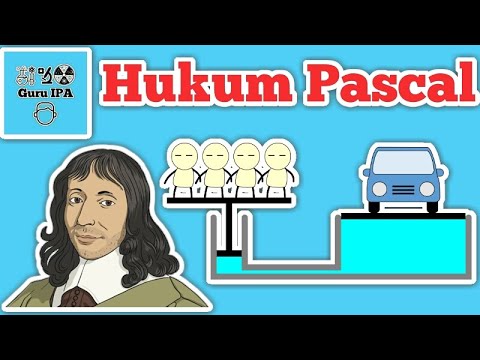

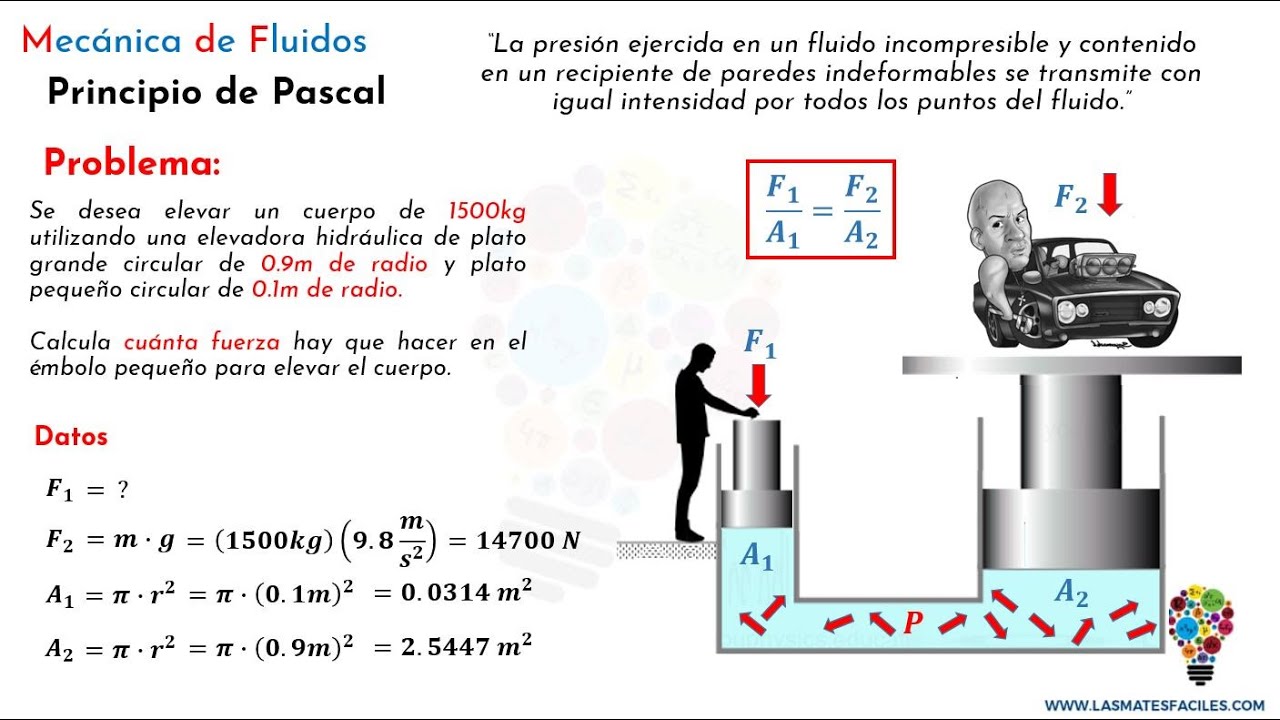

- 💧 The process utilizes hydraulic fluid, often oil, to transfer pressure during pressing.

- 🔄 The advantage of isostatic pressing is its ability to create uniform pressure, unlike traditional methods that may apply force in one direction.

- 🏗️ There are two main setups for isostatic pressing: right back and dry bag methods.

- 📦 In the right back method, powder is contained in a soft container that allows it to reshape when pressure is applied.

- 🔩 The dry bag method uses a rubber diaphragm to separate the powder from the hydraulic fluid while applying pressure.

- 🧪 Both methods are suitable for shaping complex or large samples through uniform compression.

- 🛠️ The right back method is often more complex and messy compared to the dry bag method.

- ⚙️ Automation can be applied in isostatic pressing for smaller samples to streamline the process.

- ❗ Isostatic pressing is generally reserved for special occasions due to its complexity and messiness.

Q & A

What is isostatic pressing?

-Isostatic pressing is a method that applies pressure uniformly from all directions using a fluid to transfer the pressure during the pressing process.

What are the two main setups for isostatic pressing?

-The two main setups for isostatic pressing are called 'wet bag' and 'dry bag' isostatic pressing.

How does the wet bag isostatic pressing work?

-In wet bag isostatic pressing, a hydraulic fluid (often oil) is used to apply pressure on a powder placed inside a soft container that allows for shape change.

What is the purpose of using a soft container in wet bag isostatic pressing?

-The soft container allows the powder to reshape uniformly under pressure from the hydraulic fluid.

What is involved in the dry bag isostatic pressing method?

-In dry bag isostatic pressing, a rubber diaphragm separates the powder from the hydraulic fluid, and pressure is applied to the rigid core that holds the powder.

What type of samples is dry bag pressing typically used for?

-Dry bag pressing is generally used for smaller samples or shapes, often in automated processes.

Why might wet bag pressing be considered messier than dry bag pressing?

-Wet bag pressing can be messier due to the nature of using hydraulic fluids, which can spill or create a mess during the process.

What is the advantage of isostatic pressing compared to other pressing methods?

-The main advantage of isostatic pressing is the uniform application of pressure, which can improve the quality and consistency of the final product.

What kind of applications might require isostatic pressing?

-Isostatic pressing is often used in industries requiring complex shapes or large-sized samples, such as ceramics and advanced materials manufacturing.

How is gas removed before the isostatic pressing process?

-Gas is removed as much as possible from the soft container to create a vacuum, ensuring better pressure application on the powder.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)