Crank and Cam Sensors

Summary

TLDRIn this informative video, Andy from How EFI Works discusses the critical roles of cam and crank sensors in ignition setups. He explains the operation of variable reluctance (VR) sensors and Hall sensors, detailing how they generate voltage signals that the ECU interprets. Andy also highlights the importance of proper wiring, the function of pull-up resistors, and the setup of 36-1 tooth wheels for effective engine timing. Additionally, he showcases practical examples, including different sensor types and configurations, providing viewers with valuable insights into optimizing engine performance.

Takeaways

- 😀 The VR sensor (Variable Reluctor) detects the crank position using a magnet and generates a voltage change with each tooth passing through.

- 🔋 The sensor outputs a plus and minus voltage signal, which is interpreted by the ECU to determine the crankshaft position.

- 📊 A scope can visually represent the voltage changes caused by the tooth movements, showing a clear rise and drop in voltage.

- ⚡ A Hall sensor operates similarly to a VR sensor but provides a square wave output, acting like a high-speed relay.

- 🔌 Hall sensors require a pull-up resistor to function correctly, ensuring proper voltage changes are detected by the ECU.

- 🛠️ The Cherry Hall sensor, which includes an internal pull-up resistor, simplifies wiring by eliminating the need for external resistors.

- 🔄 A typical 36-1 tooth wheel setup allows for accurate crank position tracking, with one tooth intentionally missing to aid timing.

- ⏳ The ECU can be configured to command a set advance (e.g., 10 degrees) before top dead center during cranking.

- 🌀 The relationship between crank and cam sensors is crucial, as the cam sensor provides additional timing information at a different speed.

- 🎥 The setup and configurations can be visualized using logging tools, demonstrating the sensor triggers over rotations and helping to diagnose issues.

Q & A

What is the function of a Variable Reluctor (VR) sensor?

-The VR sensor detects the position of the crankshaft by generating a voltage signal each time a tooth on the crank wheel passes by a magnet.

How does the output signal of a VR sensor appear on an oscilloscope?

-The signal shows a voltage rise when a tooth approaches the magnet, followed by an instant drop to zero as the tooth moves past, creating a recognizable waveform.

What happens if the wiring of a VR sensor is reversed?

-Reversing the wiring can lead to multiple triggers and an incorrect reading, as the ECU may misinterpret the voltage changes.

What distinguishes a Hall Effect sensor from a VR sensor?

-A Hall Effect sensor outputs a square wave signal rather than a varying voltage. It functions like a relay that switches its output state based on the position of the teeth.

What is the importance of the pull-up resistor in a Hall Effect sensor?

-The pull-up resistor is essential for ensuring that the output voltage shifts to a detectable level. Without it, the sensor may not produce a noticeable change in voltage.

How is the ignition setup configured using a 36-1 tooth wheel?

-The setup involves using a crank position sensor that detects the 36 teeth, with one missing. This configuration allows the ECU to accurately time ignition events.

What does 'tooth number one' refer to in this context?

-'Tooth number one' is the first tooth detected by the sensor after the missing tooth on the crank wheel, crucial for timing reference.

What is the purpose of cranking advance in the ECU settings?

-Cranking advance tells the ECU to command a specific timing advance (e.g., 10 degrees) before top dead center to assist with starting the engine.

What type of wheel is commonly used for the crankshaft, and why?

-A 36-1 tooth wheel is commonly used because it provides enough resolution for accurate crank position sensing while allowing for a reliable reference point with a missing tooth.

How do the cam and crank sensors work together in an engine management system?

-The cam and crank sensors work together to provide the ECU with precise timing information, allowing it to control ignition and fuel injection for optimal engine performance.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

EMS Part 1: Engine Management System I Bahasa Indonesia #ems #enginemanagementsystem

how conventional ignition systems work

CARA KERJA SISTEM STATER SEPEDA MOTOR

Cara Shooting Dengan Satu Kamera - Cara Membuat Film Pendek

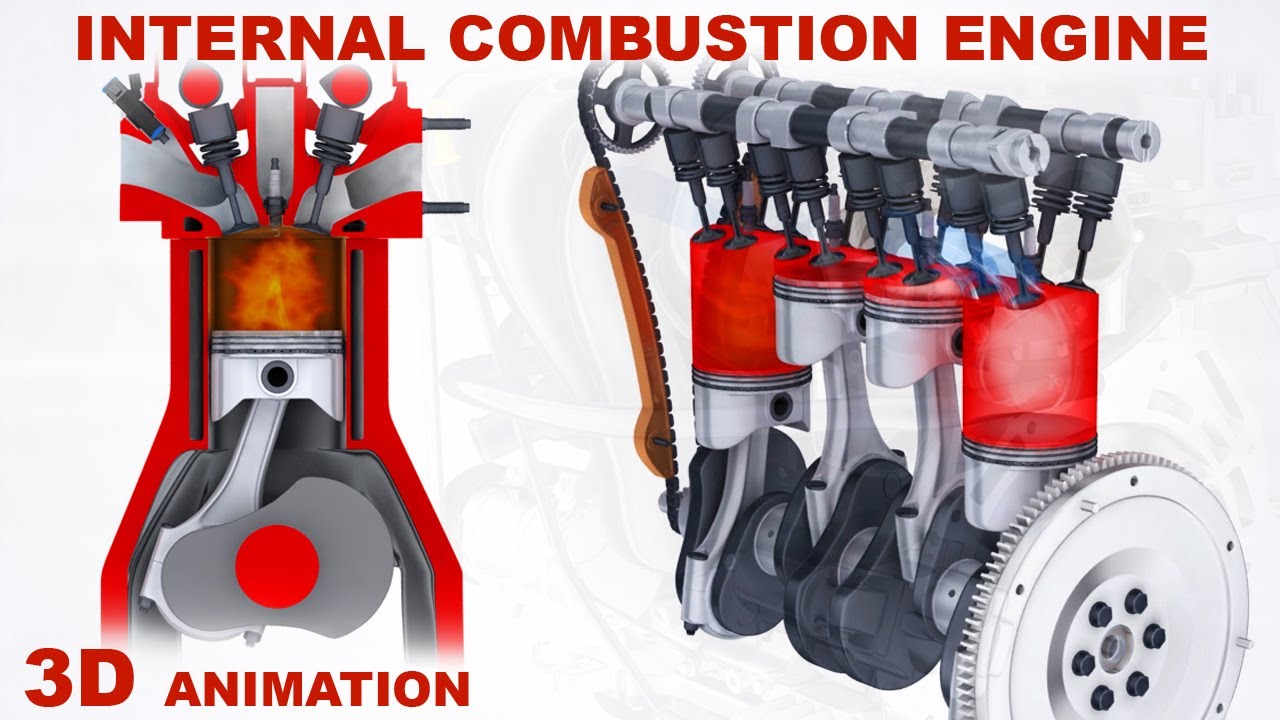

How car engine works? / 4 stroke internal combustion engine (3D animation)

Why Sensor in Carburettor bikes

5.0 / 5 (0 votes)