T-Joint Flashing | Mastering the Basics | ZIP System® sheathing and tape

Summary

TLDRThis video demonstrates proper flashing techniques when a vertical seam (TG) occurs above a window or door opening in the Zip System sheathing. It outlines three methods for flashing the intersection between the vertical seam and head flashing: 1) shingle vertical seam tape over the head flashing, 2) use 6-inch tape to cover the top flange of the window, and 3) apply two layers of 4-inch tape. Each option includes using drip edges and rolling the tape for proper installation. The video emphasizes following manufacturer guidelines for air sealing and offers more technical tips on the Zip System YouTube channel.

Takeaways

- 🛠️ The video covers proper flashing techniques when a T-joint occurs above a window or door opening.

- 🔧 The same considerations apply for T-joints above both window and door openings.

- 📏 Special attention is needed for any vertical seams that occur above window openings when flashing to the Zip System sheathing surface.

- 📋 Three options are provided for detailing the intersection between vertical seams and head flashing above a window.

- 📐 Option 1: Shingle the vertical seam tape over the top of the window head flashing, with a minimum of 2 inches overlap.

- 📏 Option 2: Use 6-inch Zip System tape to flash the window and cover the vertical seam tape.

- 🔨 Option 3: Use two layers of 4-inch Zip System tape to flash the top flange of the window.

- 💡 A tape-saving option involves using a shorter second horizontal piece that extends at least 2 inches past the vertical tape.

- 🔩 After flashing the window, install a drip edge and flash it to the Zip System tape using 4-inch tape.

- 📚 Follow manufacturer recommendations for air sealing gaps between the window frame and rough framing.

Q & A

What is the primary purpose of flashing in the context of the video?

-The primary purpose of flashing in the video is to protect the structure from water infiltration, especially at intersections like T joints above windows or door openings.

What special consideration must be given when flashing a window in the Zip System sheathing surface?

-Special consideration must be given to any vertical seams that occur above the window opening to ensure they are properly detailed and sealed.

What is the first option for detailing the intersection between a vertical seam and the head flashing?

-The first option involves shingling the vertical seam tape a minimum of two inches over the window head flashing, followed by the installation of drip edge and flashing it with 4-inch Zip System tape.

How is the 6-inch Zip System tape used in the second option?

-In the second option, 6-inch Zip System tape is used to flash the top flange of the window to the Zip System sheathing surface, ensuring proper sealing above the vertical seam.

What is the third option for flashing the top flange of the window?

-The third option involves using two layers of 4-inch Zip System tape to flash the top flange of the window. The first layer seals the flange to the sheathing, while the second layer overlaps the first by two inches.

What is the tape-saving option mentioned in the video?

-The tape-saving option involves using a shorter second horizontal piece of tape that extends a minimum of two inches past the vertical piece of tape onto the Zip System panel surface.

Why is it important to roll the tape after installation?

-Rolling the tape ensures a proper bond between the tape and the sheathing, preventing water infiltration and ensuring the flashing system functions effectively.

What is the purpose of the drip edge in the flashing process?

-The drip edge directs water away from the window or door opening, reducing the risk of water entering the structure and protecting the head flashing from potential water damage.

What are the manufacturer's recommendations for air sealing the window opening?

-The manufacturer recommends following guidelines for air sealing the gap between the window frame and the rough framing on the inside of the window opening to prevent air and moisture infiltration.

Where can viewers find more technical tips and product information?

-Viewers can find more technical tips and product information by visiting YouTube at youtube.com/zip_system_sheathing.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Avoiding Window Leaks: How to Flash Window Jambs | ZIP System sheathing and tape

Repairing Hairline Cracks and Why They Appear on Window and Door Corners

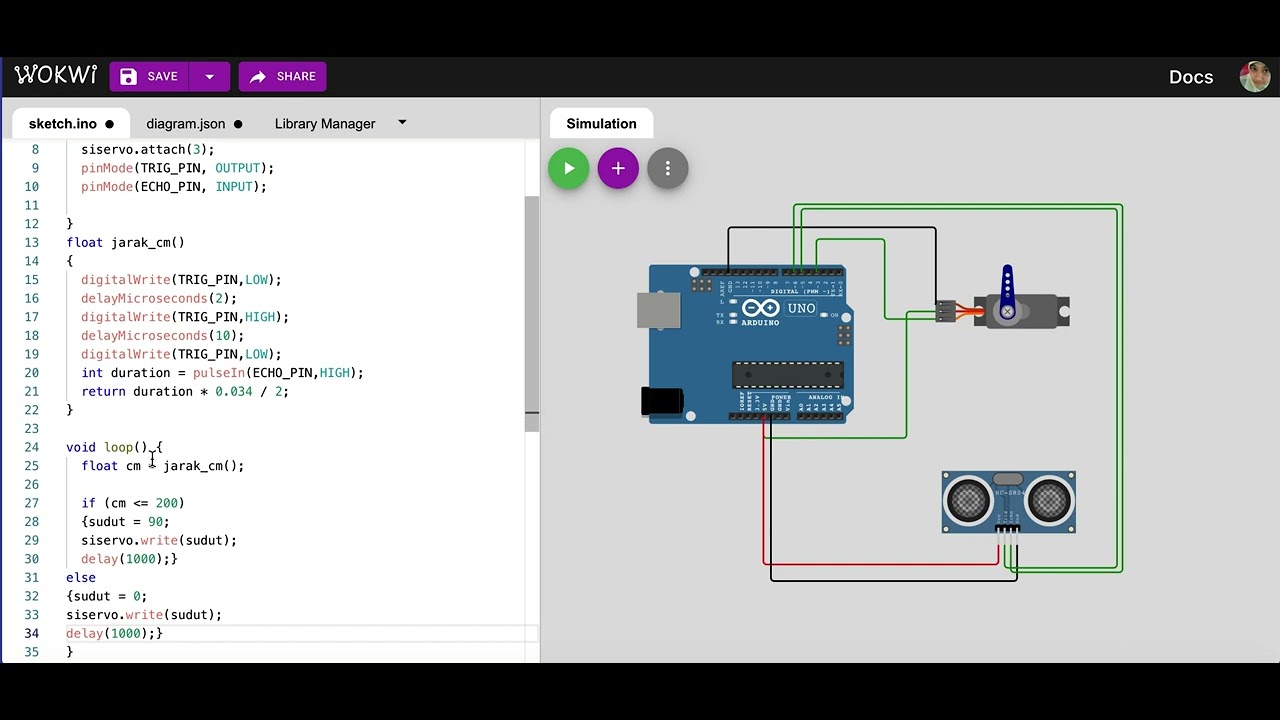

Simulasi kontrol gerakan servo dengan sensor ultrasonik | mikrokontroler arduino di wokwi.com

My New Shop: Installing Zip R-Sheathing and Roof Sheathing

How to make a ZIP Files in Windows

8 MOVING EDGES ABSOLUTE AND RELATIVE

5.0 / 5 (0 votes)