FUEL INJECTORS - How They Work | SCIENCE GARAGE

Summary

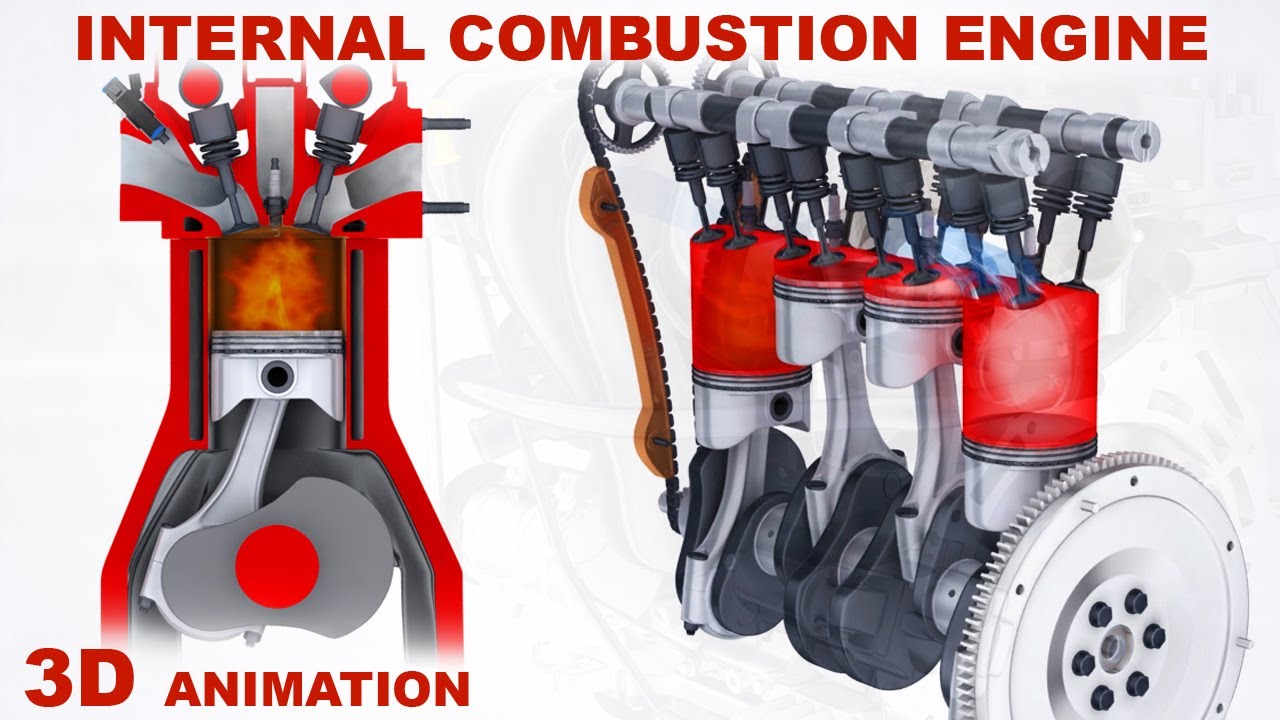

TLDRThis video delves into the intricacies of fuel injectors, essential for optimizing an engine's fuel and air mixture. It contrasts fuel injection with carburetors, highlighting benefits like improved cold starts and fuel efficiency. The script explains three types of fuel injection: port, direct, and indirect, each with its mechanisms and advantages. It also touches on the historical shift from carburetors to fuel injection and the unique aspects of diesel engines. Sponsored by Squarespace, the video is part of a series exploring automotive technology.

Takeaways

- 🚗 Engines operate on a mix of fuel and air, with fuel injectors playing a critical role in delivering this mixture efficiently.

- ☕ The ideal fuel-to-air ratio for complete combustion in engines is 14.7:1, known as a stoichiometric air-fuel ratio.

- 📡 Fuel injectors are controlled by the car's computer, which times the fuel spray to work in concert with the spark plug for optimal combustion.

- 💧 There are three main types of fuel injection systems: port, direct, and indirect, each with its own method of delivering fuel to the engine.

- 🏭 Port fuel injection is cost-effective and self-cleaning for intake valves but is less efficient compared to other systems.

- 💉 Direct fuel injection offers better fuel economy and power but can lead to higher temperatures and carbon buildup in the cylinders.

- 🌀 Wall-guided and spray-guided are two subtypes of direct fuel injection, each using different methods to mix fuel with air within the cylinder.

- 🖱️ Indirect fuel injection, specific to diesel engines, uses a pre-ignition chamber to ignite a mixture of fuel and air before it enters the cylinder.

- 🌟 Mazda's SkyActiv-X HCCI engine combines the benefits of diesel and gasoline engines, achieving high fuel efficiency and reduced pollutants.

- 🛠️ The video also humorously touches on the challenges and maintenance aspects of different fuel injection systems, like carbon buildup and the need for glow plugs.

Q & A

What is the ideal fuel to air ratio for complete combustion in an engine?

-The ideal fuel to air ratio for complete combustion in an engine is 14.7 to one, meaning for every one unit of fuel, 14.7 equivalent units of air at sea level are needed.

What are the benefits of fuel injection over carburetors?

-Fuel injection offers benefits such as easier cold starts, better fuel efficiency, more consistent transient throttle response, and sometimes variability of fuel delivery depending on drive modes.

How does a fuel injector work?

-A fuel injector is fed by the fuel rail and uses an electromagnetic coil to pull the plunger up, opening the pintle injector and spraying fuel out of the nozzle. The sprays happen multiple times every second, with each spray delivering an exact amount of fuel controlled by the car's computer.

What are the three types of fuel injections commonly seen in modern cars?

-The three types of fuel injections commonly seen in modern cars are port injection, direct injection, and indirect injection.

How does port injection differ from direct injection?

-In port injection, fuel is delivered via separate fuel injectors at the intake manifold, above the intake valve. In contrast, direct injection involves fuel being sprayed directly into the cylinder, either guided by the cylinder wall or spray pattern.

What is the purpose of the swirl cavity in wall guided fuel injection?

-The swirl cavity in wall guided fuel injection is designed to create a vortex of air, which helps mix vaporized fuel with the air for efficient combustion when ignited by the spark.

How does indirect fuel injection work in diesel engines?

-Indirect fuel injection in diesel engines uses a pre-ignition chamber where fuel and air are pre-ignited before being delivered to the cylinder. This process ensures complete mixing and efficient combustion.

What is the advantage of direct injection over port and indirect injection?

-Direct injection allows for better fuel economy, more power, and doesn't require the intake valves to be open for it to function, which means the injectors are not dependent on the timing of the intake valves.

What are the potential issues with direct injection systems?

-Direct injection systems can lead to higher temperatures and pressure, causing stress on the cylinders. They are also more costly to produce and are prone to carbon buildup around the intake valves.

What is Mazda's SkyActiv-X HCCI engine and how does it relate to fuel injection?

-Mazda's SkyActiv-X HCCI engine combines the high compression and fuel efficiency of diesel engines with the reduced pollutants of gasoline engines. It utilizes techniques involving turbulence in direct fuel injection to achieve this.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Carburetor vs Fuel Injection - Why Motorcycle Riders Should Think Again

Reversing of Marine Diesel Engine

How car engine works? / 4 stroke internal combustion engine (3D animation)

Sistem EFI #1 - Gambaran Umum Kerja Sistem Injeksi

Inyección de gasolina, tipos, partes, función.

CARA KERJA SISTEM BAHAN BAKAR MESIN DIESEL

5.0 / 5 (0 votes)