The Bessemer Process of Manufacturing Steel

Summary

TLDRThis video delves into the Bessemer process, a pivotal method for steel production invented by Henry Bessemer. It highlights the essential resources like coal and iron, and describes the process involving furnaces and Bessemer converters to purify molten iron into steel. The video underscores the historical significance of this method in reducing steel costs from $50 to $9 per ton, enabling mass production for infrastructure and machinery. It also discusses the environmental impact of steel factories and the subsequent benefits to the economy and job creation, emphasizing steel's enduring importance in modern construction and industry.

Takeaways

- 🔥 The Bessemer process was a significant innovation in steel manufacturing, allowing for the mass production of quality steel.

- ⛏️ Key resources for steel production included coal, which was used for heating and powering machinery, and iron, which was the primary reactant in the steel-making chemical reaction.

- 🏭 Steel factories were typically located near cities for convenience, but this led to pollution issues due to the smoke produced by the factories.

- 👷♂️ Workers in iron mines often labored in harsh conditions, with long hours and difficult work environments.

- 🔧 The Bessemer converter, invented by Henry Bessemer, was central to the process, using hot air to oxidize and remove impurities from molten iron.

- 🔥 The process involved seven major steps, including the use of the Bessemer converter to purify steel by oxidizing impurities and adding alloys to create steel.

- 📉 The Bessemer process dramatically reduced the cost of steel production, from about $50 per ton to around $9 per ton, making steel more accessible for a variety of uses.

- 🚂 Steel became widely used in construction, engineering, machinery, and transportation, including train tracks, which revolutionized how people and goods moved.

- 🏗️ The process led to job creation and the development of new cities around steel factories, as the demand for steel increased.

- 🌐 Today, steel remains an essential material for the global industrial economy, used in various applications due to its strength, durability, and relative lightness.

Q & A

What is the Bessemer process?

-The Bessemer process is a method of manufacturing steel from molten pig iron in a way that removes impurities such as carbon. It was invented by Henry Bessemer and was a significant development in the mass production of steel.

Why was coal important in the steel-making process?

-Coal was crucial for making steel as it was used to generate heat for furnaces and to power machines in steel factories through the conversion of water into steam.

What role did iron play in the Bessemer process?

-Iron was the key reactant in the chemical reaction to make steel. It was mined and then transported to steel factories where it was used in the Bessemer process.

Where were steel factories typically located and why?

-Steel factories were usually located near cities. This proximity made the workers' commute shorter but also led to pollution due to the smoke produced by the factories.

How did the Bessemer converter work?

-The Bessemer converter worked by blowing air through molten iron to oxidize and remove impurities. This process created a flame at the top of the converter and resulted in the production of steel.

What were the seven major steps in the Bessemer process?

-The seven major steps included transporting iron ore to factories, melting the ore into molten impure iron, pouring it into a ladle, transferring it to a Bessemer converter, blowing hot air to oxidize impurities, adding alloys to create steel, and finally, pouring the molten steel into ingot molds.

How did the Bessemer process impact the cost of steel production?

-The Bessemer process significantly reduced the cost of steel production, from about $50 per ton to around $9 per ton, making steel more affordable and accessible for mass use.

What were some benefits of the Bessemer process?

-The Bessemer process allowed for the inexpensive mass production of steel, which was faster and more efficient than previous methods. It also led to the creation of jobs and the development of new cities around steel factories.

How did the use of steel change with the advent of the Bessemer process?

-With the Bessemer process, steel became widely used in construction, engineering, machinery, and transportation, leading to advancements in various industries and improving people's lives.

What is the significance of steel in today's world?

-Steel is essential to the world's industrial economy due to its strength, durability, and versatility. It is used extensively in construction, particularly for skyscrapers, stadiums, and other types of buildings.

How did the Bessemer process affect the development of new inventions?

-The Bessemer process made steel more accessible and affordable, which in turn facilitated the development of new inventions and innovations, as steel became a key material in various industries.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

TECHNOLOGICAL Innovation in the Gilded Age [APUSH Review Unit 6 Topic 5] Period 6: 1865-1898

The Gilded Age part 2 | The Gilded Age (1865-1898) | US History | Khan Academy

The Secret Behind the "I-Beam" Strength

What is Industrialization?

SS.912.A.3.2 Causes of the Second Industrial Revolution

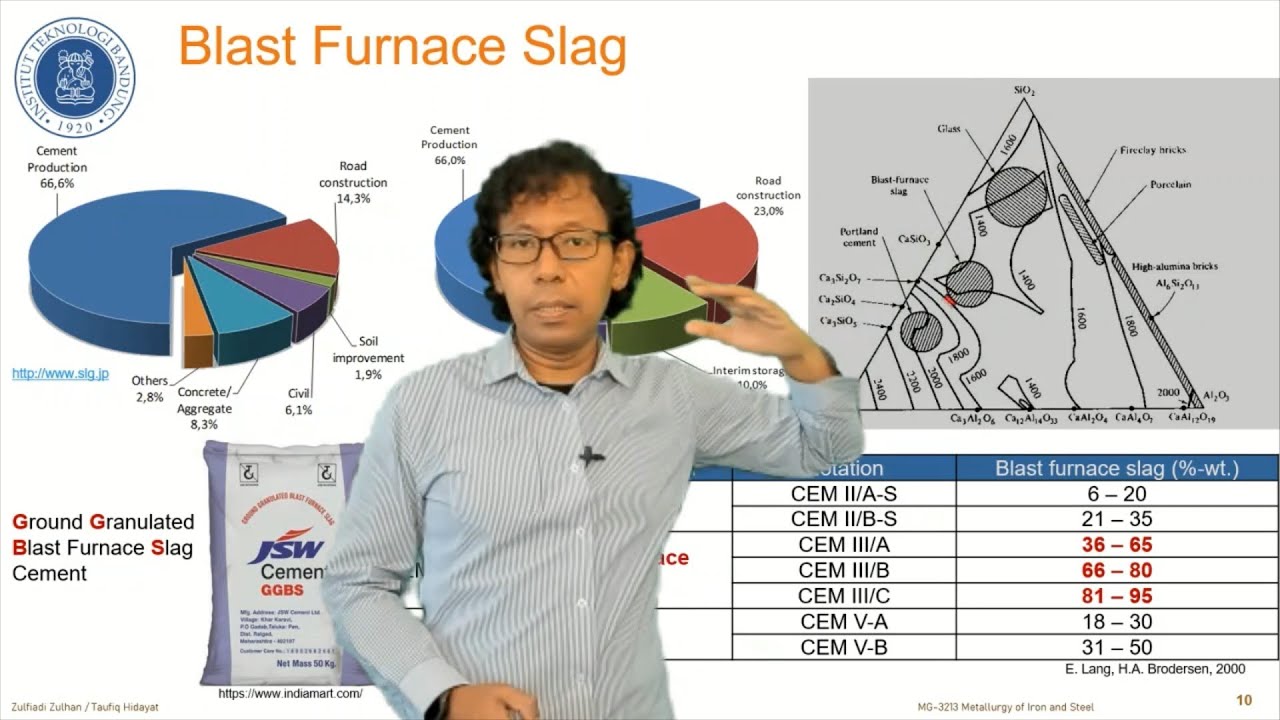

03. Metalurgi Besi Baja, S05 - Blast Furnace Slag, Cement

5.0 / 5 (0 votes)