Engenharia da qualidade - seminário

Summary

TLDRThis seminar explores the career opportunities in quality engineering, highlighting its five subareas: quality systems management, planning and control, standardization, metrological organization, and reliability of processes and products. It discusses the key roles and responsibilities within each area, relevant certifications, and methodologies like ISO 9001 and Six Sigma. The seminar also covers salary ranges, educational requirements, and how these fields contribute to business optimization and competitiveness. Through real-world examples and industry insights, it emphasizes the importance of quality assurance and continuous improvement in various sectors, including manufacturing, healthcare, and more.

Takeaways

- 😀 Quality engineering is divided into five subareas: quality system management, planning and control, standardization, auditing and certification, metrological organization, and process/product reliability.

- 😀 The main goal of the seminar is to explore the importance of quality assurance within optimization processes in businesses, enhancing organizational competitiveness.

- 😀 Quality engineers are responsible for implementing and managing quality systems within organizations, ensuring high standards in products and services delivered to customers.

- 😀 Popular quality system management models include ISO 9001, Six Sigma, Lean Manufacturing, and PDCA (Plan-Do-Check-Act), all of which utilize statistical methods to improve business processes.

- 😀 The salary of professionals in the quality system management field can vary between $4,000 to $12,000 depending on position, education, and experience level.

- 😀 Planning and control in quality engineering focus on analyzing and controlling processes, with tools like Statistical Process Control (SPC), Fishbone Diagram, and Pareto Diagram to ensure consistency and identify areas for improvement.

- 😀 In the planning and control area, the salary for quality analysts ranges from $3,500 to $9,000, influenced by experience, education, and the company's size.

- 😀 Standardization in quality engineering ensures product excellence and process optimization, with industries like food, healthcare, and construction relying heavily on technical standards like ISO 9001 and other national regulations.

- 😀 Metrology plays a critical role in ensuring measurement accuracy and involves calibration of measurement instruments. It is used in industries such as aerospace, automotive, and healthcare.

- 😀 Process and product reliability engineers focus on analyzing and optimizing systems using methods like FMEA (Failure Mode and Effects Analysis), RCM (Reliability-Centered Maintenance), and FTA (Fault Tree Analysis), with salaries ranging from $5,000 to $15,000 depending on the role and sector.

Q & A

What is the primary goal of the seminar on Quality Engineering?

-The primary goal of the seminar is to explore the subfields within Quality Engineering in Brazil, focusing on the importance of quality assurance in organizational processes and competitiveness, as well as the roles of engineers within these areas.

What are the five subareas within Quality Engineering discussed in the seminar?

-The five subareas within Quality Engineering discussed are: 1) Management of Quality Systems, 2) Planning and Control, 3) Standardization, 4) Auditing and Certification, 5) Metrological Organization and Reliability of Processes and Products.

What is the role of engineers in the Management of Quality Systems?

-Engineers in the Management of Quality Systems are responsible for planning, implementing, and managing quality systems within organizations, ensuring that products or services meet customer expectations and maintain high quality standards.

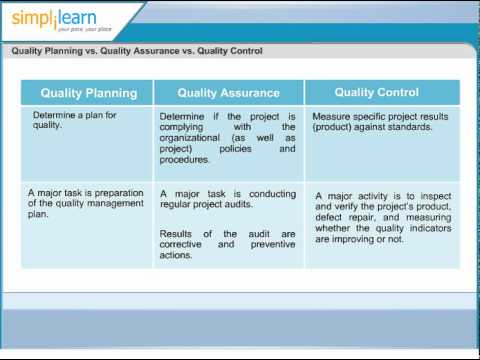

What are some of the quality management models commonly used in organizations?

-Some of the most commonly used quality management models include ISO 9001, Six Sigma, Lean Manufacturing, and PDCA (Plan, Do, Check, Act). These models help organizations improve their quality systems using statistical analysis and process management.

What factors influence salary variation within the Management of Quality Systems?

-Salary variation within the Management of Quality Systems is influenced by factors such as job position (analyst, consultant, manager), education level, work experience, and the size or nature of the company.

How does Planning and Control contribute to quality in organizations?

-Planning and Control focuses on analyzing and controlling processes to ensure consistency and meet quality standards. It involves tools like statistical control and process diagrams (e.g., fishbone diagrams, Pareto charts) to identify and correct faults in production or service delivery.

What are some common tools used in Planning and Control for quality management?

-Common tools used in Planning and Control include the Statistical Process Control (SPC), Fishbone Diagrams (Ishikawa), Pareto Diagrams, and others. These help identify, prioritize, and solve issues within the production or service process.

What is the importance of standardization in Quality Engineering?

-Standardization is essential in Quality Engineering because it ensures products and services meet established criteria and regulations, improving consistency and efficiency. It also helps industries maintain compliance with international standards like ISO and other industry-specific regulations.

How does Metrology contribute to quality assurance?

-Metrology ensures that measurement instruments are calibrated accurately and uncertainties are identified and managed. This is critical in industries requiring high precision, such as aerospace, automotive, and medical equipment, to ensure product quality and safety.

What is the focus of Reliability Engineering in Quality Engineering?

-Reliability Engineering focuses on analyzing and optimizing processes and systems to minimize failures. It uses techniques like FMEA (Failure Mode and Effect Analysis), RCM (Reliability-Centered Maintenance), and others to improve the reliability and performance of products or services.

What is the significance of ISO 9001 in Quality Engineering?

-ISO 9001 is a critical standard for Quality Management Systems, defining requirements for maintaining high-quality processes and continuous improvement. It is widely recognized globally and helps organizations ensure customer satisfaction and improve their operational efficiency.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)