Bab 1 Menganalisis perencanaan produksi massal (Produk kreatif dan kewirausahaan)

Summary

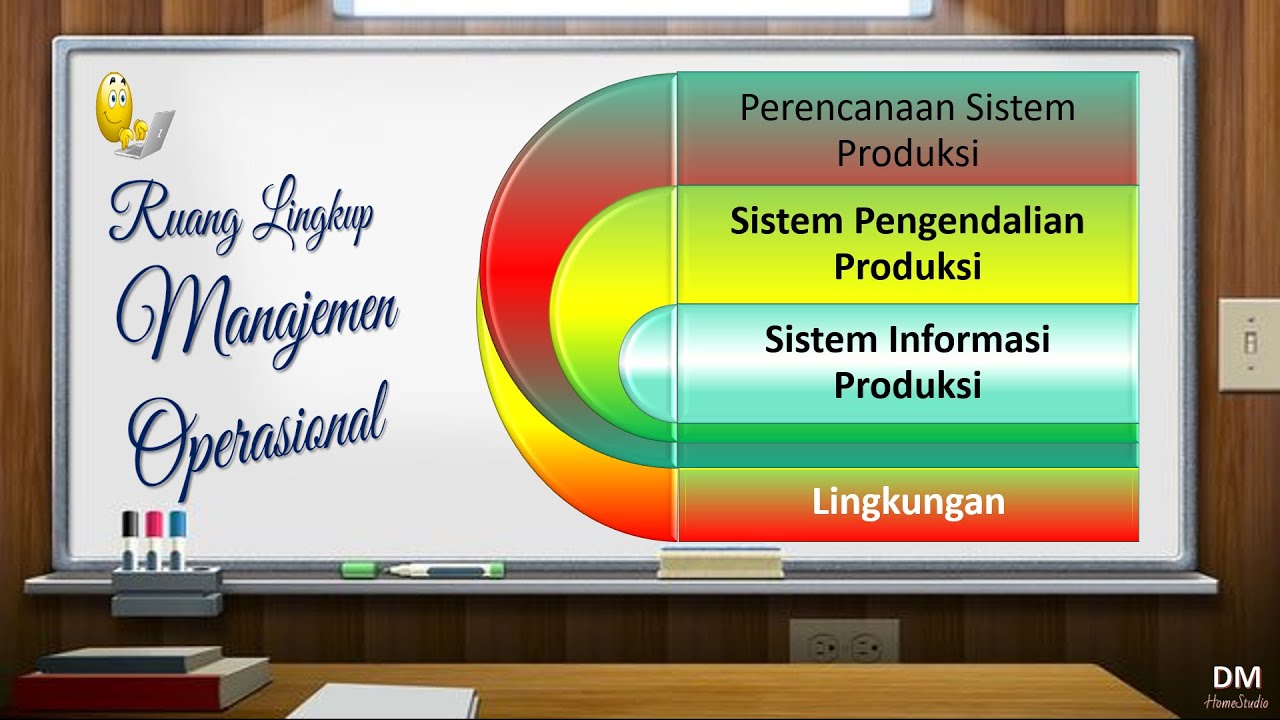

TLDRThe video script introduces the concept of mass production planning from an educational perspective, detailing its definition, characteristics, and importance in fulfilling consumer needs. It covers the stages of production planning, including market analysis, product life cycle, and cash flow, emphasizing the benefits of mass production such as high accuracy and automation, while also acknowledging its drawbacks like resource waste and lack of diversity. The script further discusses the planning process, from product idea selection to implementation, and the significance of production control for ensuring customer satisfaction and organizational success.

Takeaways

- 😀 Mass production is an activity to create goods or services with value to meet the needs of individuals or organizations.

- 🔍 Key characteristics of mass production include clear standards, continuous production machinery, balanced production flow, relatively short production time, automatic raw material usage, and ease of production control.

- 📈 The concept of 'utility value' refers to the benefits derived from the use of a product, which can be tangible or intangible.

- 🛠 Types of utility value include basic utility, time utility, right utility, form utility, service utility, and ownership utility.

- 📝 Production planning encompasses preparing a production plan from an aggregate level for the entire factory, including market demand forecasts and sales projections.

- ⏳ Different types of production planning are distinguished based on the time frame, such as short-term operational planning and long-term capacity planning.

- 🔑 The features of production planning include preparing for future activities, having a specific time frame, coordinating production activities, and ensuring the quality and quantity of products meet the planned requirements.

- 🎯 The functions and purposes of production planning include aligning with sales and strategic plans, ensuring production capacity matches the plan, monitoring actual production results, and adjusting schedules and inventory.

- 🚀 Advantages of mass production include high accuracy and automation, reduced labor costs, increased production levels, and low per-unit costs and waste.

- 🔄 Disadvantages of mass production include wasted resources, lack of variety, difficulty in changing products, and challenges in adapting to changes in demand and order fluctuations.

- 📊 The stages of production planning include market research, product life cycle analysis, cash flow assessment, and organizational capability evaluation.

- 🛑 Indicators of successful mass production include characteristics such as enthusiasm for new opportunities, disciplined pursuit of opportunities, focus on execution, and involving energy and people within their reach.

Q & A

What does Heni introduce in the beginning of the script?

-Heni introduces herself as a student from class 12 TKJ 1 and mentions that she will explain the subject of PKK, specifically chapter 1 about analyzing mass production planning.

What is the definition of mass production according to the script?

-Mass production is defined as an activity to create or produce goods or services that have value to meet the needs of individuals or organizations.

What are the main characteristics of mass production mentioned in the script?

-The main characteristics of mass production include having clear standards in the production process, the use of machinery that can continuously produce goods in large quantities, balanced production flow, relatively short production time, automatic use of raw materials, and ease in production control.

What is the concept of 'utility of goods' as described in the script?

-The utility of goods refers to the value or benefit derived from the use of a product, which can be tangible or intangible. A product is considered useful if it can provide benefits and is valuable if it has utility.

Can you explain the types of utility of goods mentioned in the script?

-The types of utility of goods include basic utility, time utility, place utility, form utility, service utility, and ownership utility.

What does the script say about production planning according to Sukaria Sinulingga (2013)?

-According to Sukaria Sinulingga, production planning includes preparing a production plan from an aggregate level for the entire factory, including market demand forecasts, sales projections, scheduling the completion of each product, planning production and external components, and scheduling operational processes for each order at related workstations.

How does Enny Aryani (2009) differentiate between short-term and long-term production planning?

-Enny Aryani differentiates between short-term production planning, which is operational and determines production activities within one year or less to arrange labor, materials, and facilities, and long-term production planning, which determines production activities over more than one year, usually five years, to plan for capacity expansion, equipment, or machinery, and product development.

What are the advantages of mass production as outlined in the script?

-The advantages of mass production include high accuracy and automation, low labor cost, high production volume, low per-unit expenditure, reduced wastage, low labor cost, and low material handling costs in the factory.

What are the disadvantages of mass production mentioned in the script?

-The disadvantages of mass production include wasted resources, lack of guarantee, higher costs for materials, lack of diversity, difficulty in changing products, susceptibility to production stoppages, and difficulty in dealing with changes in demand levels.

What are the stages of mass production planning as described in the script?

-The stages of mass production planning include market research, product life cycle analysis, cash flow assessment, organizational capability evaluation, product idea selection, initial design, prototype testing, detailed design, and implementation.

What are the indicators of successful mass production according to the script?

-The indicators of successful mass production include having an entrepreneurial mindset with enthusiasm for new opportunities, disciplined pursuit of opportunities, focus on execution, and involving energy and people within their reach.

How does the script describe the process of production?

-The script describes the production process as a series of stages involved in producing goods and services, including preparation for production, establishment of the business, and the actual production process which can be short, long, continuous, or intermittent.

What is the purpose of production planning as mentioned in the script?

-The purpose of production planning is to ensure the right quantity and quality of raw materials and equipment are available during production, to utilize capacity according to demand forecasts, and to benefit from efficient production to reduce overall product costs.

What are the basic strategies managed by production planning according to the script?

-Production planning manages two basic strategies: product planning, which determines what products will be produced, and process planning, which determines how the products will be produced.

What are the benefits of production monitoring and control as described in the script?

-The benefits of production monitoring and control include ensuring the smooth flow of all production processes, controlling production costs to increase company profits, managing resources, and maintaining quality standards through the production monitoring cycle.

What factors can cause deviation from production planning according to the script?

-Deviation from production planning can be caused by factors such as unavailability of raw materials or auxiliary materials due to shortages or quality issues, machine breakdowns, changes in demand, order cancellations, order additions, or changes in delivery times, worker absenteeism, lack of coordination and communication between units, suppliers, or customers.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)