Air Separation Unit

Summary

TLDRAn air separation unit (ASU) is a facility used to separate atmospheric air into its primary components: nitrogen, oxygen, and argon. The process begins with filtering and compressing the air, followed by cooling to remove unwanted gases. After passing through a temperature swing absorber, the air undergoes cryogenic cooling, reaching temperatures as low as -196°C. Inside a cold box, oxygen, nitrogen, and argon are separated through liquefaction and distillation. The final products are liquid oxygen, liquid argon, and gaseous nitrogen, ready for use in various industrial applications.

Takeaways

- 😀 Air Separation Units (ASUs) are industrial facilities used to separate atmospheric air into its primary components: nitrogen, oxygen, and argon.

- 😀 The process starts with air being filtered to remove dust and particles before being compressed to six times its normal pressure.

- 😀 After compression, the air temperature increases from 20°C to about 90°C. The air then passes through a heat exchanger cooled by cold water.

- 😀 The air is cooled to 10°C while maintaining a high pressure, just below ambient temperature.

- 😀 CO2 and hydrocarbons are removed from the air through a temperature swing absorber to prevent solid formation and flammability issues.

- 😀 The temperature swing absorber uses pellets to absorb CO2 and other unwanted compounds, which are easily released when the pellets are heated.

- 😀 The absorber has two tanks: one active and one inactive, with the active tank cooled by liquid nitrogen to absorb unwanted compounds.

- 😀 After the air is processed through the temperature swing absorber, it contains only nitrogen, oxygen, and argon, ready for cryogenic cooling.

- 😀 The air is cooled further using a Joule-Thomson cooler, where it reaches -120°C. Pre-cooling helps achieve even lower temperatures.

- 😀 In the cold box, the air is separated into liquid oxygen, liquid argon, and gaseous nitrogen based on their boiling points, with nitrogen at the top, argon in the middle, and oxygen at the bottom.

Q & A

What is an air separation unit (ASU)?

-An air separation unit (ASU) is an industrial facility used to separate atmospheric air into its primary components: nitrogen, oxygen, and argon.

How does the air separation process begin in an ASU?

-The process begins by forcing ambient air through a particulate filter to remove dust and small airborne particles.

Why is the air compressed in an air separation unit?

-The air is compressed to six times its normal pressure to prepare it for cooling, which is necessary for the separation of its components.

What happens to the air after it is compressed in the ASU?

-After compression, the temperature of the air increases from 20°C to about 90°C due to the compression process.

How is the high-temperature compressed air cooled in the ASU?

-The compressed hot air is passed through a heat exchanger, which is cooled by cold water, reducing the temperature to 10°C while maintaining high pressure.

What is the purpose of the temperature swing absorber in the ASU?

-The temperature swing absorber is used to remove unwanted compounds, like CO2 and hydrocarbons, which could block the air flow or cause hazardous reactions when mixed with oxygen.

What is the role of the pellets in the temperature swing absorber?

-The pellets in the absorber are designed to absorb CO2 and other unwanted compounds, sticking to their surface, and these compounds are later released when the pellets are heated.

What happens after the air passes through the temperature swing absorber?

-After passing through the temperature swing absorber, the air consists mainly of nitrogen, oxygen, and argon, making it ready for cryogenic cooling.

How is the air further cooled to cryogenic temperatures in the ASU?

-The air is passed through a Joule-Thomson cooler, where the temperature is reduced to -120°C by utilizing the Joule-Thomson effect, and is then further cooled to -165°C using the cooled air.

How does the cold box facilitate the separation of air components?

-The cold box uses two chambers, one at high pressure and one at low pressure. The air is cooled to -173°C in the high-pressure section, causing oxygen and argon to liquefy at the bottom. The liquid oxygen is extracted, while nitrogen remains as a gas at the top and is further condensed.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

GCSE CHEMISTRY - COMPOUNDS AND MIXTURES - LESSON 8 - fractional distillation of air

OSGS Nitrogen membrane

Materi Atmosfer | Sesi 1 | Geografi

What’s in the air you breathe? - Amy Hrdina and Jesse Kroll

Pengaruh Stabilitas Atmosfer Terhadap Terjadinya Petir

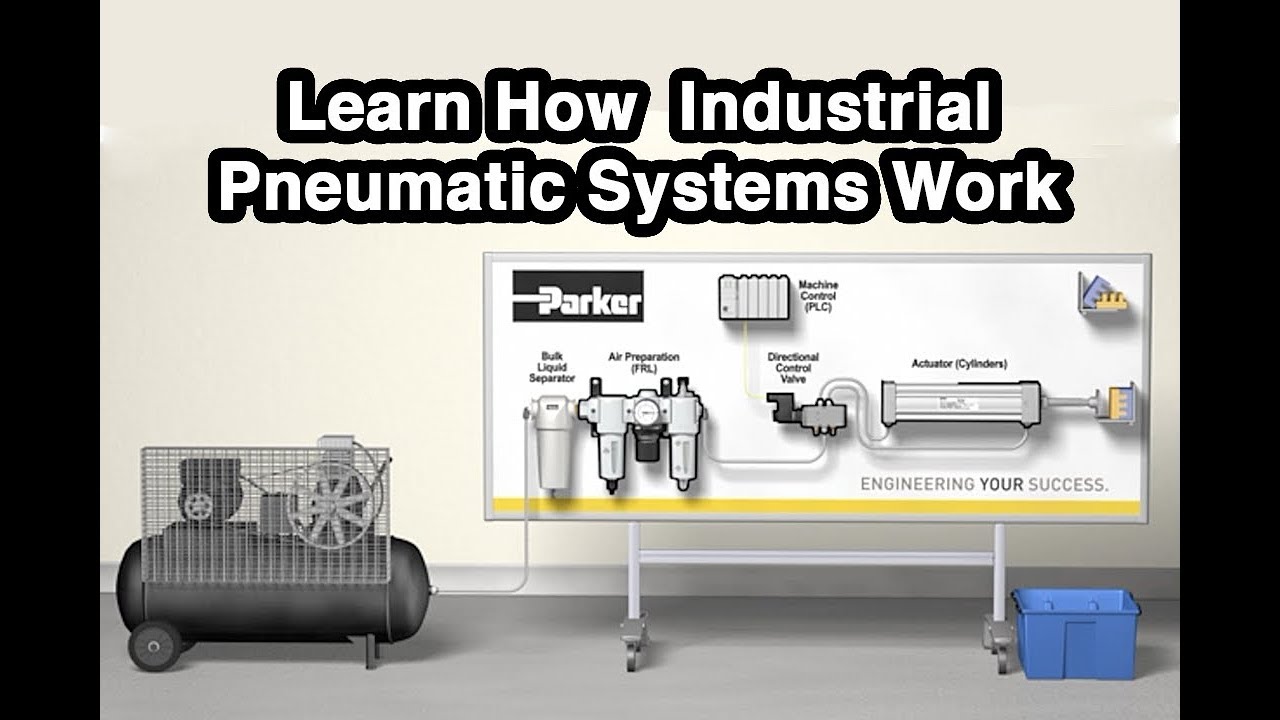

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

5.0 / 5 (0 votes)