Telecurso 2000 Processos de Fabricação 14 O arco elétrico entra em ação

Summary

TLDRThis video lesson introduces electric arc welding with the coated electrode process, focusing on its function, necessary equipment, applications, and safety protocols. Viewers learn how electric current is crucial in the welding process, and how different types of electrodes, along with various welding positions and polarities, affect the results. The video also covers essential equipment like the welding power source, electrode holder, and protective gear. The instructor provides a thorough overview of welding preparation, electrode selection, and proper techniques, ensuring viewers understand both theoretical and practical aspects of arc welding.

Takeaways

- 😀 The video introduces a professional course on welding, specifically focusing on electric arc welding using coated electrodes.

- 😀 The course consists of 80 lessons, with the current lesson covering the first 14 lessons.

- 😀 Electric arc welding is explained, emphasizing the importance of electric current and its types: direct current (DC) and alternating current (AC).

- 😀 The process of electric arc welding involves creating an electric arc between the positive electrode and the negative metal base to generate enough heat to fuse the materials.

- 😀 A transformer, rectifier, or generator is required to adjust the voltage and current needed for welding tasks.

- 😀 There are two main types of electrode polarity: direct polarity (where the base metal is positive) and reverse polarity (where the electrode is positive). Each has different heat distribution characteristics.

- 😀 The electrode is classified using a specific numerical code that indicates its minimum tensile strength, the welding positions it can be used in, and its compatibility with certain currents.

- 😀 The protective coating on electrodes plays a key role in shielding the weld pool from atmospheric contamination and stabilizing the arc.

- 😀 It is crucial to select the right electrode for the specific type of welding task, and electrodes are categorized by their performance and recommended uses.

- 😀 Proper handling and storage of electrodes, especially those sensitive to moisture, is essential for ensuring quality welds. Safety equipment like gloves, protective masks, and boots are necessary for protecting against burns and radiation during welding.

Q & A

What is the focus of this module in the professional training course?

-The module focuses on different welding techniques, specifically the process of electric arc welding with a covered electrode, which is one of the most important and widely used methods in the aerospace and mechanical industries.

What is the main difference between continuous and alternating current in welding?

-Continuous current flows in a single direction, while alternating current changes direction periodically. Electric arc welding uses alternating current, which is the type of current typically received in homes through electrical transmission lines.

What equipment is necessary for electric arc welding?

-The necessary equipment includes a transformer, rectifier, or generator, which transforms the electrical energy into the appropriate voltage and current intensity for the welding process.

How does the electric arc form during welding?

-The electric arc forms when the positive electrode and the negative metal base come close together, causing free electrons to collide with atoms and molecules. This generates high temperatures that fuse the metal base and the electrode, creating the fusion pool.

What is the role of the electrode in electric arc welding?

-The electrode serves as the positive pole in the welding process and melts to provide filler material for the weld. The electrode is coated with a protective layer to prevent contamination and improve the weld quality.

What are the two types of electrode polarity in electric arc welding?

-The two types of electrode polarity are direct polarity (where the base metal is the positive pole and the electrode is negative) and inverse polarity (where the electrode is positive and the base metal is negative). The choice of polarity affects the heat distribution and the penetration of the weld.

Why is electrode selection important in welding?

-Electrode selection is critical because it determines the quality and suitability of the weld. Electrodes are classified by their resistance to traction, the positions in which they can be used, and the type of current and polarity required for the weld.

What are the functions of the coating on the welding electrode?

-The coating of the electrode protects the weld from atmospheric contamination, helps to stabilize the arc, slows down the solidification rate of the molten metal, and creates a protective slag that further ensures weld quality.

How should welding electrodes be stored to ensure optimal performance?

-Welding electrodes should be stored in a dry, controlled environment, such as special ovens, because they are sensitive to moisture. This prevents them from absorbing water, which could negatively impact the weld quality.

What safety equipment is essential when performing electric arc welding?

-Essential safety equipment includes gloves, aprons, protective masks, hoods, and safety boots. These protect the welder from burns, radiation, and other hazards associated with welding.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

SMAW WELDING | Working animation of shielded metal arc welding process | Arc Welding

Stick Welding Basics: Full Tutorial

Materiais e Processos de Fabricação para Engenharia de Produção - Princípios de soldagem

What is STICK Welding? (SMAW)

LAS SMAW (shield metal arc welding) pengertian dan keuntungan Las Listrik

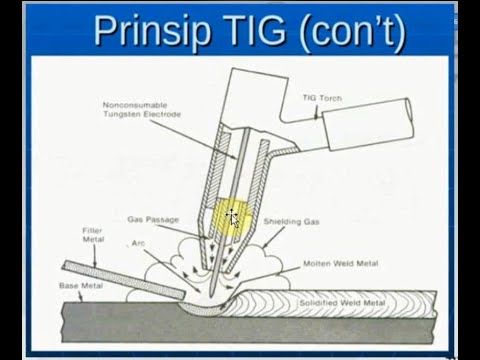

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

5.0 / 5 (0 votes)