[Toyota Production System] Jidoka: Avoiding Simple Mistakes Through Poka-yoke Device

Summary

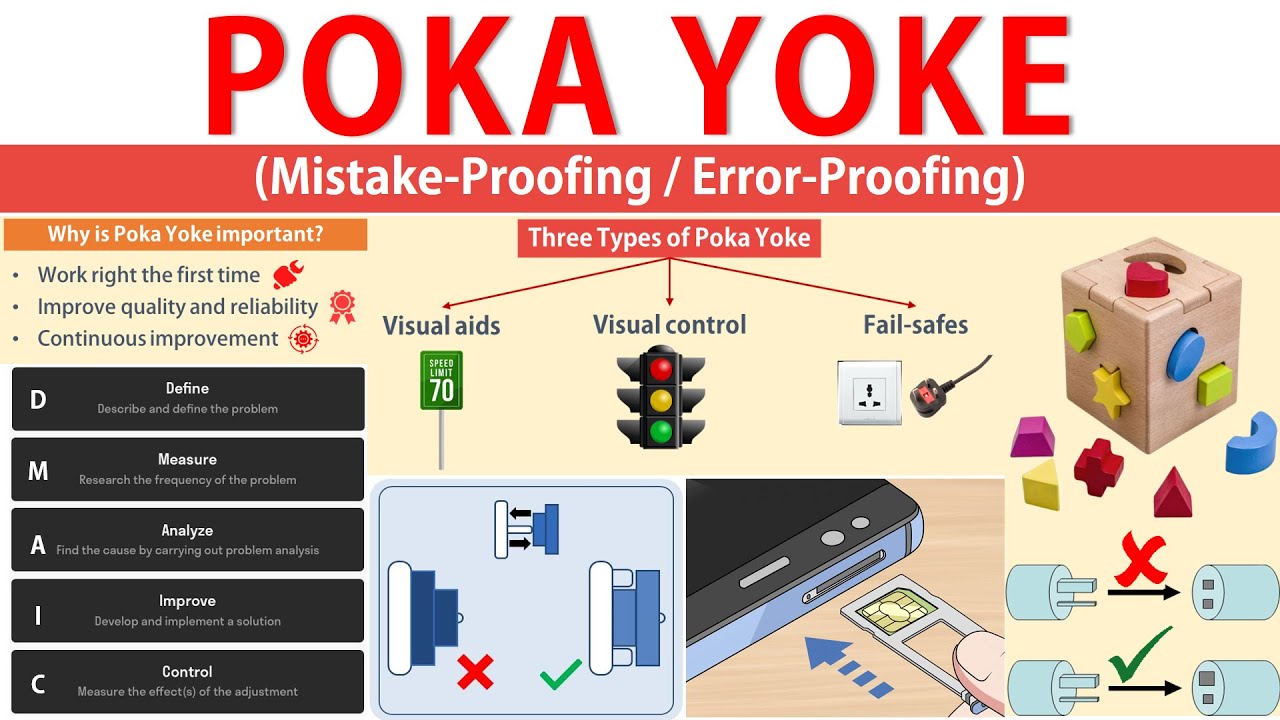

TLDRThe video introduces the concept of a poka-yoke or fail-safe device linked to an electric screwdriver used for tightening screws. It visually alerts workers through a traffic light system: orange indicates a check is needed, red signals a loose screw, and green confirms that the screw is tightened. This system enhances error prevention by stopping the assembly line if an error goes unnoticed, exemplifying how technology can significantly improve safety and efficiency in manufacturing processes.

Takeaways

- 🔧 The device mentioned is called pocoyoke, a type of fail-safe device.

- ⚙️ The pocoyoke is linked to an electric screwdriver used for checking loose screws.

- 🟠 The light indicator starts as orange, signaling the system is active.

- 🔴 If there is a loose screw, the light turns red, visually notifying the worker.

- 🟢 When the screw is tightened, the light changes to green, indicating the task is complete.

- ⏹️ The system automatically stops the line if an error is not caught by the worker.

- 🔍 Pocoyoke devices help in preventing errors or highlighting them as they occur.

- 🛠️ Such systems enhance safety and quality control in manufacturing processes.

- 👷♂️ Workers receive immediate feedback on their tasks through visual indicators.

- ✅ The pocoyoke exemplifies effective engineering solutions aimed at reducing human error.

Q & A

What is a pocoyoke device?

-A pocoyoke, also known as a fail-safe device, is designed to prevent errors in manufacturing or assembly processes.

How does the pocoyoke work with an electric screwdriver?

-The pocoyoke is linked to an electric screwdriver and monitors for loose screws, indicating their status through visual signals.

What do the different light colors indicate?

-The light starts as orange, turns red when a loose screw is detected, and turns green when the screw is tightened properly.

What happens if a worker does not catch an error?

-Even if the worker does not notice an error, the production line will automatically stop to prevent further issues.

Can you give an example of how pocoyoke devices help in error prevention?

-Pocoyoke devices help highlight errors in real-time, allowing workers to correct them as they occur, thus reducing defects.

What is the main purpose of using pocoyoke devices in a production line?

-The main purpose is to enhance quality control by preventing mistakes and ensuring that tasks are completed correctly.

What visual signals does the pocoyoke provide?

-The pocoyoke provides visual signals through colored lights that indicate the status of the screws being checked.

How does the pocoyoke contribute to workplace safety?

-By preventing errors and stopping the line when issues are detected, pocoyoke devices contribute to a safer working environment.

What might be the impact of not using a pocoyoke in assembly lines?

-Without a pocoyoke, there is a higher risk of errors going unnoticed, which can lead to defective products and increased costs.

Are there other applications for pocoyoke devices besides checking screws?

-Yes, pocoyoke devices can be applied in various contexts to prevent different types of errors and ensure quality control.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Poka Yoke (Error Proofing) - Meaning, Concept, Types, Stages, & Implementation Explained.

Understanding Japanese Culture 3

Basic Mechanical Maintenance

Herramientas de calidad - Poka Yoke, Kaizen y Kan Ban

Ncuti Gatwa's New Sonic Screwdriver | Doctor Who

DIY EMP Device from a Harbor Harbor Freight Fly Swatter

5.0 / 5 (0 votes)