How to Remove (Recover) Refrigerant From a Running AC System

Summary

TLDRThis video explains how to remove refrigerant from a running AC system efficiently and safely. It covers connecting a liquid line to a recovery cylinder, using tools like an analog manifold and core depressor to control the flow and prevent losses. The video discusses monitoring system operation, ensuring the tank is properly vacuumed, and hitting the target subcooling temperature. It also emphasizes the importance of not pulling the suction side into a vacuum to avoid compressor damage. Additional tips on refrigerant management and system disassembly are provided.

Takeaways

- 🔧 The video demonstrates how to remove refrigerant from a running AC system if the compressor is operational.

- 📉 The goal is to remove enough refrigerant without pulling the system into a vacuum, as this can damage the compressor.

- 🔄 Use a liquid line to connect to a recovery cylinder to extract the refrigerant efficiently.

- 🧰 The video highlights the use of a core depressor tool to reduce losses and control refrigerant flow better.

- 🧪 To monitor system operation, connect a suction gauge and use a line temperature clamp to measure the liquid line temperature.

- 📊 For a TXV system, ensure to check and compare the indoor TXV subcooling with target values to determine overcharge or undercharge.

- 🧮 Calculate the water capacity (WC) and convert it to the actual refrigerant weight capacity for safe tank usage.

- 💨 Before filling a new recovery tank, pull a vacuum on the tank to below 500 microns, preferably closer to 300 microns.

- 📏 Use a scale to measure the refrigerant amount precisely while charging or removing from the system.

- 🚫 Avoid pulling the suction side pressure down to zero or into a vacuum, as this can harm the compressor.

Q & A

What is the main topic of the video?

-The video explains how to remove refrigerant from a running air conditioning system, particularly when the compressor is operational.

Why is it important not to pull the system down into a vacuum during refrigerant removal?

-Pulling the system into a vacuum can damage the compressor, as the system is not designed to operate with a vacuum on the suction side.

What tool is used to control refrigerant flow and reduce losses?

-A core depressor tool is used to help control refrigerant flow, reduce losses, and prevent blowback of refrigerant during removal.

Why is it important to monitor the system operation with a suction gauge?

-Monitoring with a suction gauge allows you to keep track of the system's operation and ensure that the refrigerant removal process is done safely and effectively.

What should be done before putting a new recovery tank into operation?

-Before using a new recovery tank, you should pull a vacuum on the tank to remove air and moisture. The vacuum should be pulled down to below 500 microns.

What is 'subcooling' and why is it significant in this process?

-Subcooling refers to the temperature difference between the condensing temperature and the liquid line temperature. It is significant because the correct level of subcooling ensures the system is properly charged. In this video, the system has 20 degrees of subcooling, but the target is 10 degrees, indicating overcharging.

How do you measure the amount of refrigerant to remove?

-You compare the measured liquid line temperature and condensing temperature to determine the current subcooling. If the subcooling is higher than the target, refrigerant should be removed gradually while monitoring the system.

What is the WC or 'water capacity' of a recovery tank?

-WC (Water Capacity) is the total amount of liquid water that a recovery tank can hold. However, only 80% of this capacity should be used for refrigerant to allow for safe expansion.

What safety precautions should be taken when removing refrigerant from the system?

-Ensure that the suction side does not drop into a vacuum or reach zero pressure, as this can damage the compressor. Also, always monitor the subcooling and refrigerant levels carefully.

How is refrigerant in the gauges and hoses handled after removal?

-After removing refrigerant from the system, the refrigerant in the gauges and hoses is fed back into the suction side to prevent waste and ensure no refrigerant is lost.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Tutorial isi freon AC untuk pengguna AC

AC 5. Pengisian Freon, Pengosongan, Pevakuman, Pengisian Oli Kompressor AC | Refrigrant Conditioning

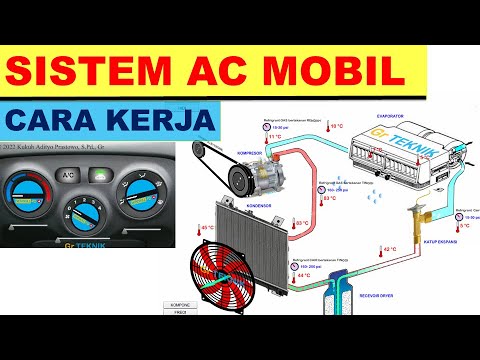

cara kerja sistem ac mobil dengan animasi siklus refrigasi freon

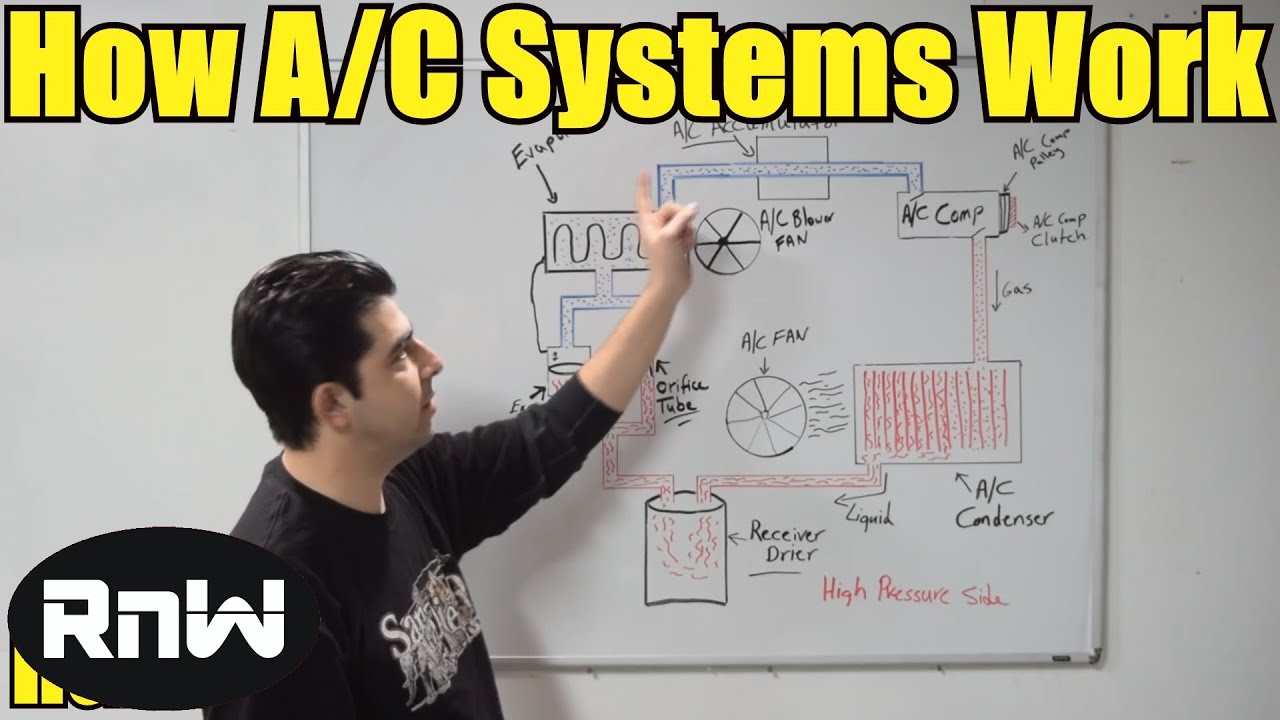

How a Car AC System Works - For Beginners

Belajar sirkulasi freon AC untuk pemula agar bisa servis atau perbaiki AC

cara kerja sistem ac mobil

5.0 / 5 (0 votes)