Nhìn ra thế giới: Ứng dụng công nghệ in 3D trong cuộc sống | Truyền hình Quốc hội Việt Nam

Summary

TLDRThis transcript explores the revolutionary impact of 3D printing technology across various industries. It highlights how 3D printing is transforming traditional manufacturing, from automotive production to aerospace and even construction. Key applications include building 3D-printed cars, creating custom parts for vehicles, and constructing homes in developing regions. The transcript also delves into the use of 3D printing for food production, such as lab-grown meat, showcasing its potential to disrupt industries. The discussion reflects on both the advantages and challenges of integrating 3D printing into mainstream production, hinting at a future where innovation accelerates product development and customization.

Takeaways

- 😀 3D printing technology has revolutionized traditional manufacturing processes by building objects layer by layer, using materials like plastics, metals, and even organic materials.

- 😀 3D printing is poised to be a major trend in industries ranging from automotive to healthcare, with significant potential for future applications in a variety of fields.

- 😀 Traditional car manufacturing involves assembly lines, which, while efficient, are not flexible. 3D printing offers a more adaptable approach to vehicle design and production.

- 😀 The world's largest 3D printer, used for producing large-scale vehicle parts, demonstrates the potential of this technology in automotive manufacturing.

- 😀 3D printing can reduce production time significantly. Traditional car manufacturing can take 5 to 7 years, while 3D printed vehicles can be designed, tested, and produced in just 12 months.

- 😀 A company used 3D printing to create the world’s first fully 3D-printed car, which was successfully showcased at an international trade show despite technical challenges.

- 😀 The use of 3D printing in cars allows for faster customization and innovation, enabling companies to quickly adapt to changing consumer demands and trends.

- 😀 3D printing is not just limited to vehicles but has also been applied in aerospace, where it helps reduce the weight of engine components, among other benefits.

- 😀 While 3D printing technology is advancing rapidly, it is still not capable of replacing traditional factories for large-scale production, especially when hundreds of thousands of units are needed.

- 😀 3D printing technology is also expanding into other industries like construction, where drones are being used to 3D print buildings in hard-to-reach or disaster-stricken areas, improving efficiency and safety.

- 😀 The food industry is experimenting with 3D printing technology, as evidenced by a company in Israel producing plant-based meat using 3D printing, showcasing the diverse potential of this technology in various sectors.

Q & A

What is 3D printing technology and how has it impacted traditional manufacturing processes?

-3D printing technology has revolutionized traditional manufacturing by offering a new method of production. Instead of using conventional processes like forging, machining, or cutting, 3D printing builds objects layer by layer under computer control. This approach is compatible with a wide range of materials, including plastics, metals, ceramics, and even organic materials, allowing for more flexible and efficient manufacturing.

What makes 3D printing a viable alternative to traditional manufacturing methods in industries like automotive?

-In the automotive industry, 3D printing allows for faster prototyping and production of parts with complex geometries. The technology enables companies to produce vehicle parts in much shorter times, reducing the time from design to production by as much as five times compared to traditional methods, offering greater flexibility and customization.

How does 3D printing enable innovation in vehicle design and manufacturing?

-3D printing allows for rapid iteration and modification of vehicle designs. For example, car manufacturers can prototype entire vehicle bodies or parts without the need for traditional molds or tooling, significantly speeding up the design process. It also supports the customization of designs for specific needs and market demands, making it easier to test and deploy new ideas.

What role did large-scale 3D printing play in the creation of the world's first fully 3D-printed car?

-The world's first fully 3D-printed car was created using an innovative 3D printing machine capable of building large parts. This involved using a computer program to provide step-by-step instructions for the machine, which layered materials to create the car's body. Despite challenges, the project succeeded and showcased the potential of 3D printing in producing complex automotive designs.

What challenges did the team face while creating the world's first 3D-printed car?

-The team faced significant technical challenges, particularly in terms of the machine's capabilities and the complexity of printing large vehicle parts. There was also a high level of skepticism from critics who doubted the feasibility of printing an entire car. Despite these challenges, the project succeeded, demonstrating that large-scale 3D printing can be used in vehicle manufacturing.

What are some real-world applications of 3D printing in the automotive industry today?

-Today, 3D printing is used in the automotive industry for rapid prototyping, custom parts manufacturing, and creating lightweight components. Companies like Ford and BMW use 3D printing to create prototype parts and even produce discontinued parts for older vehicles. The technology is also used in creating lightweight engine components in the aerospace sector to improve fuel efficiency.

How can 3D printing impact the construction industry?

-3D printing in construction is poised to revolutionize the industry by enabling the creation of buildings in hard-to-reach or hazardous locations. Drones and robotic systems can print structures layer by layer, reducing the need for labor-intensive manual construction. It also offers the potential for cost savings, quicker build times, and greater accuracy in design, with precise control over materials.

What are some of the benefits of 3D printing in the food industry?

-3D printing in the food industry, such as the production of plant-based meat, allows for customization of texture, flavor, and nutritional content. Companies are using large-scale 3D printers to create meat products like steaks with plant-based ingredients, reducing reliance on animal farming. This can lead to more sustainable food production and a reduction in environmental impact.

What is the future potential of 3D printing in other industries?

-The future potential of 3D printing is vast, with applications across many industries, including healthcare, aerospace, and food production. In healthcare, it could enable the printing of personalized medical implants and prosthetics, while in aerospace, it could help create lighter, stronger parts for aircraft. In food, 3D printing could allow for tailored, sustainable, and more ethical food production.

What are the limitations of 3D printing technology and how might they be addressed?

-While 3D printing offers many advantages, its current limitations include slower production speeds and material constraints, making it unsuitable for mass production at scale. The technology is also not yet cost-effective for high-volume manufacturing. However, advancements in machine efficiency, material science, and print speed are expected to overcome these limitations in the near future.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

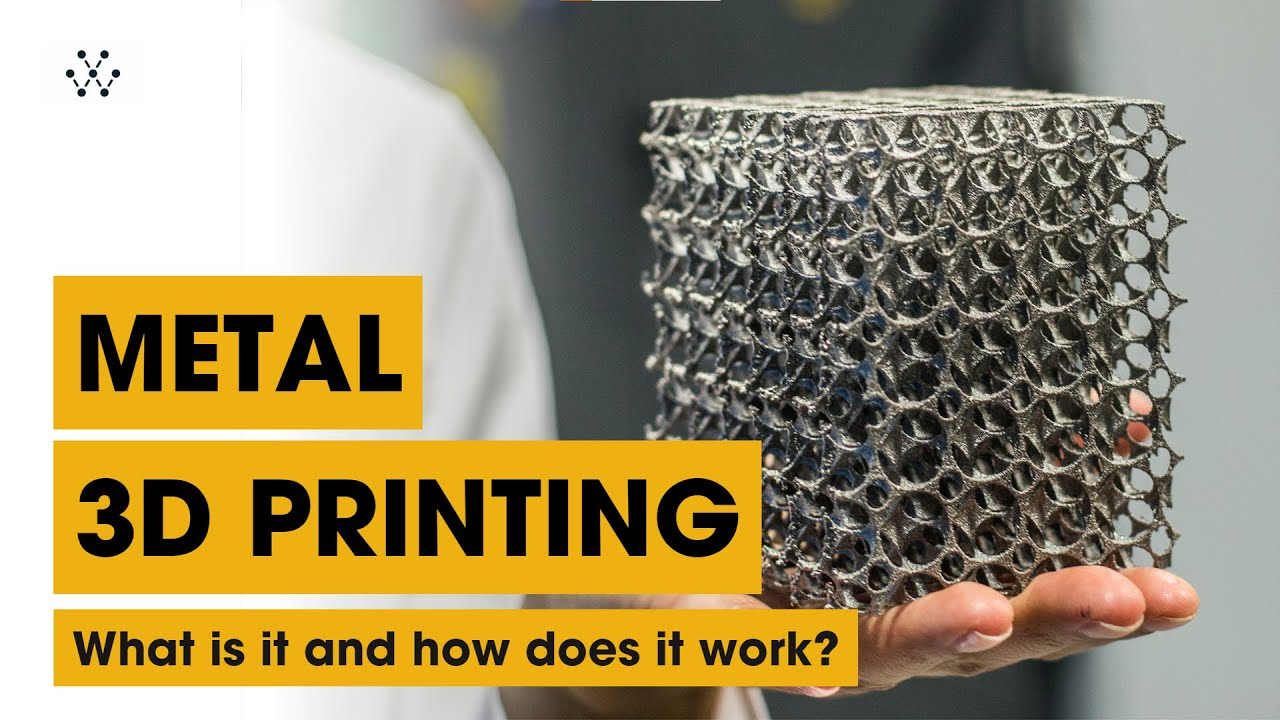

METAL 3D PRINTING | What is it and how does it work ?

The Ultimate List of What We Can 3D Print in Healthcare - The Medical Futurist

Convergência. A quarta revolução industrial.

Democratizing Design for Sustainable Future | Ridhi Khosla Jalan | TEDxDFBEDU

O que é Indústria 4.0 ?

Aula: Impressão 3D: aplicações industriais da manufatura aditiva

5.0 / 5 (0 votes)